15

MZ-E10

5-5-5.Current Amplifier (L) adjustment method

1. Connect TP953 to TP959 on the main board.

2. Set the test mode.

3. Set the Manual mode and set the item No. to 752.

LCD display

752

ChgI L XX

4. Press

key to write the adjustment value.

5-5-6. Adjustment value change method 2

(when using Version 1.000)

1. Set in Manual mode and then set item number 026.

LCD display

026

NvWrt CC

2. Press the

key.

LCD display

026

8200

**

This section (address) flashes.

3. Press the

key (100th place) and the

VOL +

key (10th

place) and set 828A in the flashing address section.

LCD display

026

828A

**

4. Press the

x

key.

LCD display

026

828A

**

This section (data) flashes.

5. Press the

VOL +

and

VOL –

keys and set 00 in the flashing

data section.

LCD display

026

828A

00

6. Press the

key.

7. Press the

key to return to Manual mode.

LCD display

026

NvWrt CC

8. Press the

key and write in the adjustment setting.

5-6. TEMPERATURE ADJUSTMENT

[Temperature adjustment method]

1. Set in Test mode.

2. Set in Manual mode and set the item number 014.

LCD display

014

AdjTmp XX

Adjustment setting

Item No.

3. Measure the temperature.

4. Adjust with the remote control

VOL +

and

VOL –

keys so

that the temperature value is at room temperature.

Reset value:

19h = 25

C

Adjustment range: 80h to 7Fh = -128

C

to +127

C

5. Press the

key and write in the adjustment value.

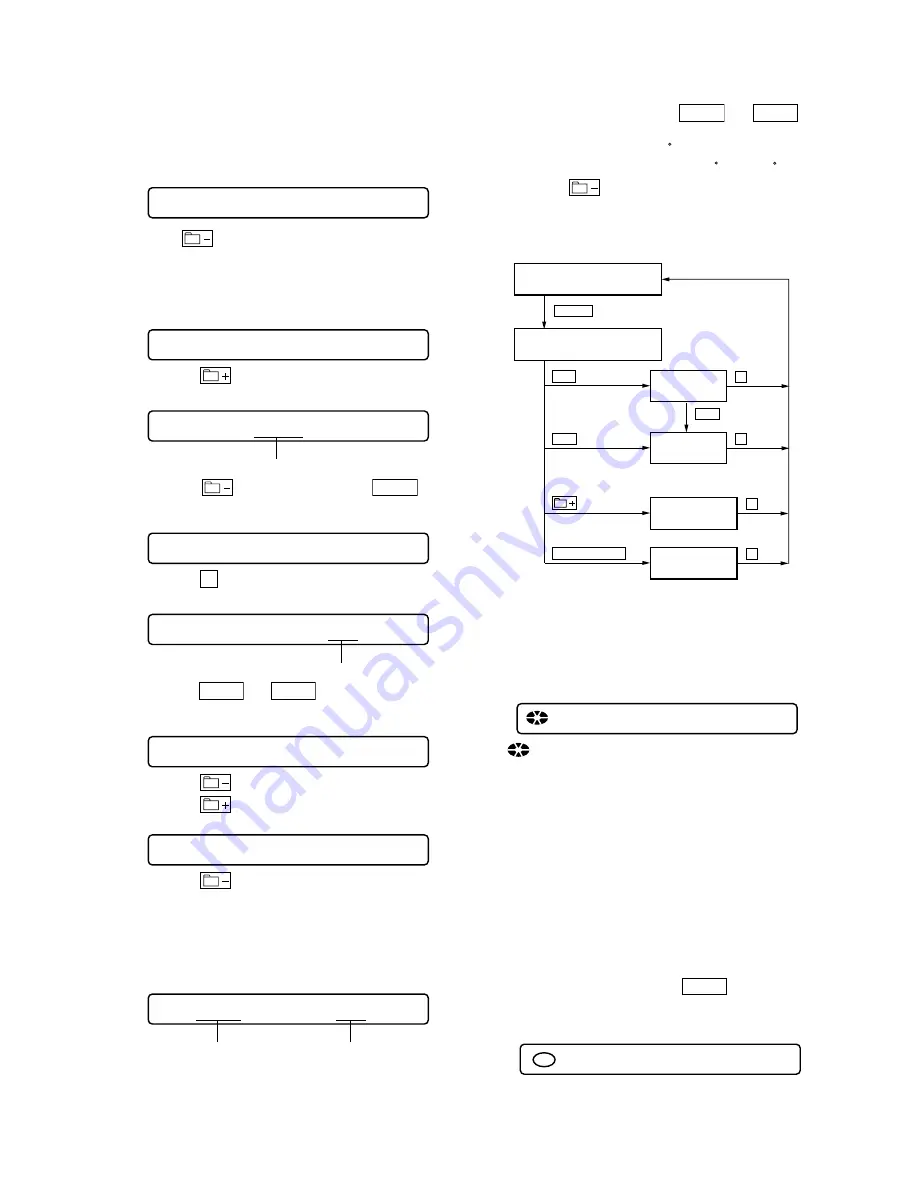

5-7. OVERALL ADJUSTMENT MODE

5-7-1. Overall adjustment mode structure

TEST MODE

(Display Check Mode)

Overall Adjustment

Title Display(ASSY**)

CD overall

Adjustment

.

key

VOL — key

key

x

MO overall

Adjustment

>

key

>

key

key

x

NV Initialize

key two times

key

x

key

x

Power Supply

Adjustment

P.MODE/

F

key

Note: The overall adjustments should be always performed in the

sequence of CD

t

MO adjustments.

5-7-2. Total Adjust mode title display

Switching to Total Adjust Mode sets the following All Adjust mode

title display on the LCD.

LCD display

000

Assy

**

: Disk mark (outer) lights up when power adjustment is com-

plete.

Disk mark (inner) not used

** : Left side is MO alignment information

F* : MO total alignment is complete

1* : Manual alignment (not part of total adjustment)

0* : Not adjusted

Right side is CD alignment information

F* : CD total alignment is complete

1* : Manual alignment (not part of total adjustment)

0* : Not adjusted

5-7-3. Overall CD and MO adjustment method

1. Set the TEST MODE and press

VOL –

key to set the Overall

Adjustment mode.

LCD display

000

Assy11

Summary of Contents for MZ-E10

Page 39: ...39 MZ E10 MEMO ...