Error value

Diagnosis

10

Path: Pin L1 → pin P7

Data: sine wave (1 kHz)

Starting serial input channel: Channel 1

Starting serial output channel: Channel 1

Error values of diagnosis items ID 0x15

Note

The signal is input to IC501 (pin M14) on the AU-342 board and is output from IC501 (pin number: shown below) to

IC1700 on the DCP-56 board (pin number: shown below).

Error value

Diagnosis

1

Path: Pin A2 → pin G22

Data: 0x55550000

Starting serial output channel: Channel 4

2

Path: Pin A2 → pin G22

Data: 0xaaaa0000

Starting serial output channel: Channel 4

3

Path: Pin A3 → pin H22

Data: 0x55550000

Starting serial output channel: Channel 6

4

Path: Pin A3 → pin H22

Data: 0xaaaa0000

Starting serial output channel: Channel 6

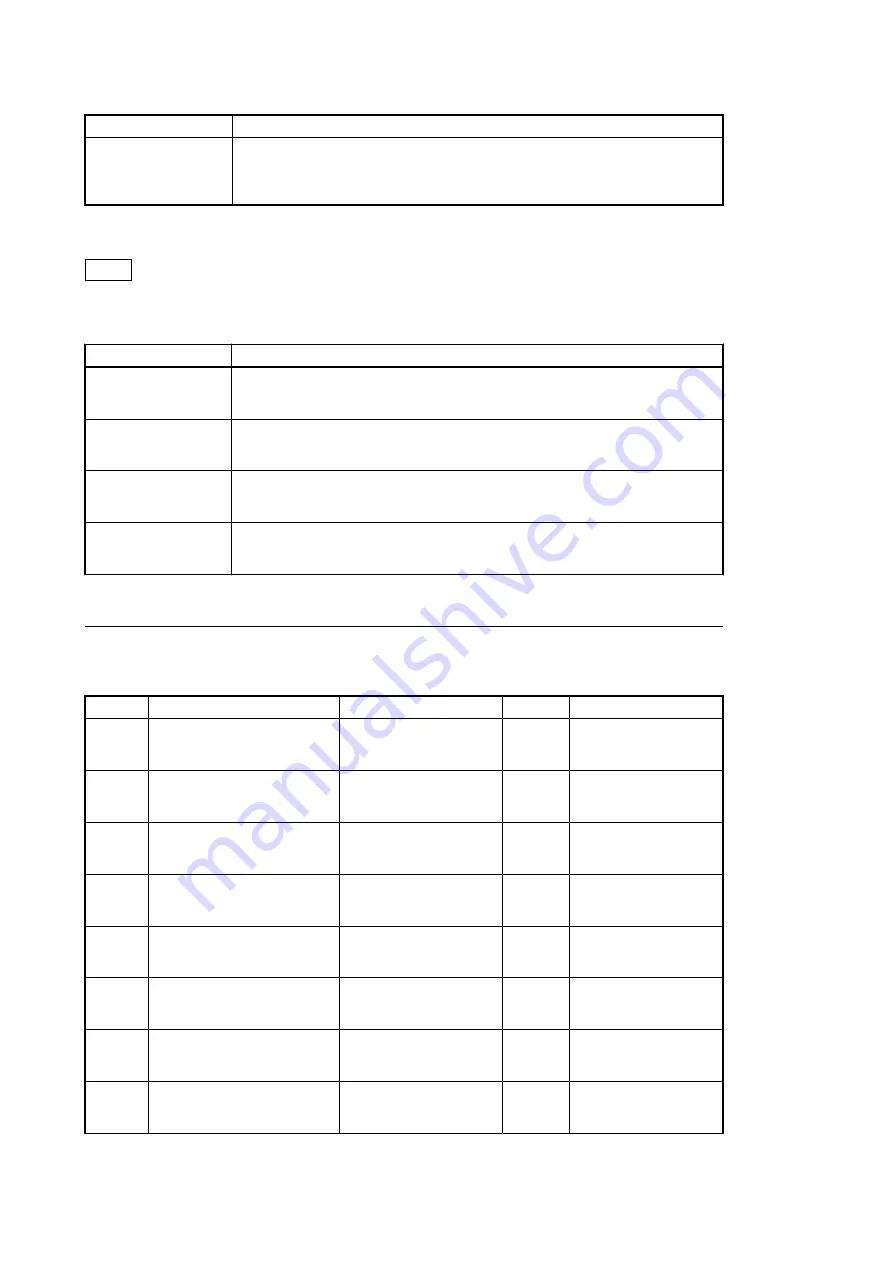

Item5 (System controller block diagnosis)

The system controller block diagnosis tests the following contents.

ID

Diagnosis

Error value

Type1/2

Note

0x01

I

2

C communication test (RTC)

-1: Error

1, 2

The unit must have started

and a sub-microcomputer

must be connected.

0x02

I

2

C communication test (EEPROM)

-1: Error

1, 2

The unit must have started

and a sub-microcomputer

must be connected.

0x03

I

2

C communication test (power sup-

ply microcomputer)

-1: Error

1, 2

The unit must have started

and a sub-microcomputer

must be connected.

0x04

I

2

C communication test (sub-micro-

computer of the inside panel)

-1: Error

1, 2

The unit must have started

and a sub-microcomputer

must be connected.

0x05

I

2

C communication test (sub-micro-

computer of the handle)

-1: Error

1, 2

The unit must have started

and a sub-microcomputer

must be connected.

0x06

I

2

C communication test (sub-micro-

computer of the rear panel)

-1: Error

1, 2

Normal end "0" is always re-

turned because there is no ap-

plicable device in this unit.

0x07

I

2

C communication test (sub-micro-

computer of the outside panel)

-1: Error

1, 2

Normal end "0" is always re-

turned because there is no ap-

plicable device in this unit.

0x08

I

2

C communication test (sub-micro-

computer of the viewfinder)

-1: Error

1, 2

Normal end "0" is always re-

turned because there is no ap-

plicable device in this unit.

Continued

PMW-200/PMW-EX280

3-10

Summary of Contents for PMW-200

Page 1: ...SOLID STATE MEMORY CAMCORDER PMW 200 PMW EX280 SERVICE MANUAL 1st Edition Revised 1 ...

Page 4: ......

Page 8: ......

Page 10: ......

Page 30: ......

Page 38: ...3 Install the removed parts by reversing steps of removal PMW 200 PMW EX280 2 8 ...

Page 82: ......

Page 96: ......

Page 128: ......

Page 130: ......

Page 132: ......

Page 133: ......