PS-HX500

12

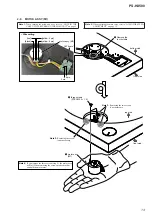

2-7. FOOT ASSY, COVER_MOTOR

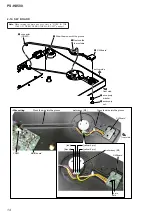

2-8. SWITCH KNOB

foot assy (rubber block)

1

Rotate the foot assy (rubber block)

in the direction of the arrow.

front side

bottom side

5

screw

(3

u

12)

2

foot assy

(rubber

block)

4

foot assy

(base

block)

3

screw

(3

u

12)

5

three screws

(3

u

12)

6

cover_motor

hole

1

Push the switch knob by

a flathead screwdriver.

How to install the switch knob

When installing the switch knob to the rotary encoder, align

the directions of the D-shaped tip of the rotary encoder and

the D-shaped notch at the inner side of the switch knob.

rotary encoder

2

switch knob

switch knob

front side

bottom side

front side

top side

Note 1:

When turning the main unit over, refer to “NOTE IN THE

CASE OF THE REVERSING THE MAIN UNIT” on page 3.

Note:

When turning the main unit over, refer to “NOTE IN THE

CASE OF THE REVERSING THE MAIN UNIT” on page 3.

Note 2:

All four foot assys ( base) can be removed using the

same procedure.