PS-HX500

PS-HX500

15

15

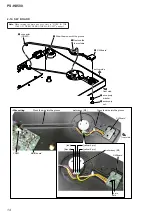

2-11. TONE ARM ASSY

[white]

[red]

wire

MAIN board

[blue/green]

:LUHVHWWLQJ

2

screw

(3

u

12)

1

Remove the

three

solders.

3

wire

rear side

hole

5

Draw the wire out

of the hole.

6

tone arm assy

front side

rear side

top side

4

six screws

(PTP3

u

14)

Note

3:

When removing the screws, make sure

that you hold the tone arm assy.

Note 2:

If you remove the six screws (step 4), the tone arm assy

will fall. When removing the screws, make sure that

you hold the tone arm assy.

Note 1:

When turning the main unit over, refer to “NOTE IN THE

CASE OF THE REVERSING THE MAIN UNIT” on page 3.

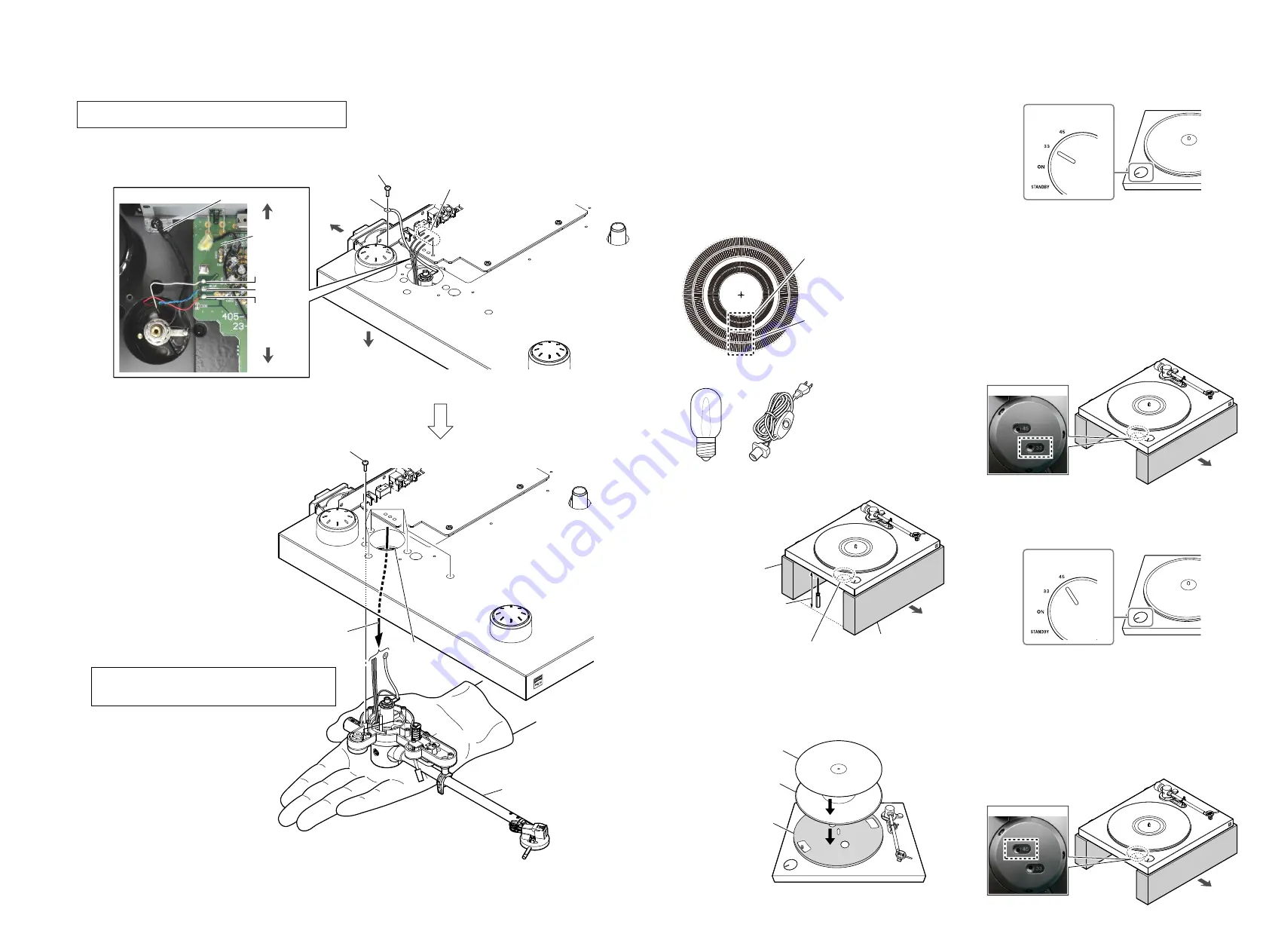

SECTION 3

ELECTRICAL ADJUSTMENT

DC MOTOR SPEED ADJUSTMENT

When replace the motor, perform the DC motor speed adjustment.

Necessary equipment:

• Speed adjustment sheet (stroboscope) (Fig A)

Note:

Enlarge “SPEED ADJUSTMENT SHEET (STROBOSCOPE)”

of page 7 and print it.

• LED light bulb without the inverter (Fig. B)

• LED light bulb socket (Fig. C)

• Insulation

fl

athead screwdriver for resistor adjustment

• Stand for putting the main unit

Power supply frequency

for 50 Hz.

inside : for 45 rpm check

outside : for 33 rpm check

Power supply frequency

for 60 Hz.

inside : for 45 rpm check

outside : for 33 rpm check

– Fig. A –

– Fig. B –

– Fig. C –

Installation method:

Holes for adjustment

(Not covered the holes by a stand)

front side

Height that the flathead

screwdriver can be used.

Stand

Stand

Procedure:

1. Installing the main unit by referring to “Installation method”.

2. Place the rubber mat onto the turntable, and place the speed

adjustment sheet (stroboscope) onto it.

Rubber mat

Turntable

Speed adjustment

sheet

3. The turntable is rotated at a rotation speed 33 rpm.

SPEED/POWER

rotary switch knob

4. Connect the socket

fi

tted with a LED light bulb into an electri-

cal outlet.

5. The LED light bulb is lit near to the turntable.

6. Insert the insulation

fl

athead screwdriver for resistor adjust-

ment into screw hole “33” at the bottom of the main unit.

Adjust the turntable speed by rotating the insulation

fl

athead

screwdriver to the left or right so that the speed adjustment

sheet pattern looks like it has stopped moving.

Note 1:

Check the applicable place of the speed adjustment sheet to match

the power supply frequency (50 Hz/60 Hz) that is used in the LED

light bulb.

front side

– Bottom view –

7. When you have completed the adjustment of 33 rpm, then per-

form the adjustment of 45 rpm.

8. The turntable is rotated at a rotation speed 45 rpm.

SPEED/POWER

rotary switch knob

9. The LED light bulb is lit near to the turntable.

10. Insert the insulation

fl

athead screwdriver for resistor adjust-

ment into screw hole “45” at the bottom of the main unit.

Adjust the turntable speed by rotating the insulation

fl

athead

screwdriver to the left or right so that the speed adjustment

sheet pattern looks like it has stopped moving.

Note 2:

Check the applicable place of the speed adjustment sheet to match

the power supply frequency (50 Hz/60 Hz) that is used in the LED

light bulb.

front side

– Bottom view –