5-20

SRW-5000/5500

PSW3

x

8

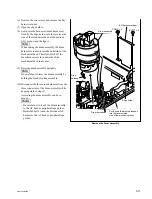

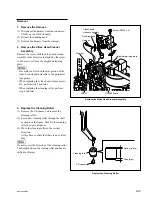

Viddeo head

cleaner assembly

Cleaning roller

A

Height determining

plate

2

1

3

H

H

H

Hours label

Full-erase head

Installation

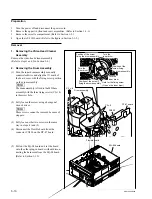

4. Attach the Video Head Cleaner

Assembly

(1) Insert the cleaning roller from the clearance

between the height determining plate and the

full-erase head.

n

Be careful not to touch the arm portion of the

video head cleaner assembly to the peripheral

tape guides.

(2) Align the two pins of the video head cleaner

assembly to the two holes of the height

determining plate.

(3) Tighten the screw while moving the video

head cleaner assembly in the direction

indicated by the arrow A (counterclockwise).

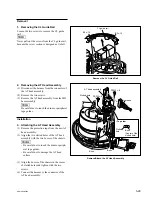

(4) Fill in the hours of the cleaning roller re-

placement on the hours label sticked on the

video head cleaner assembly.

Attach the Video Head Cleaner Assembly