– 33 –

KV-XA34M30A

RM-952

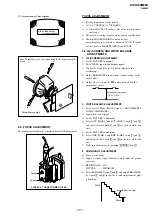

SUB HUE ADJUSTMENT

1. Select Video.

2. Input a NTSC, color-bar, into Video.

3. Set the following condition:

PICTURE 100%, BRIGHTNESS 50%, COLOR 50%

4. Connect an oscilloscope to pin

1

(B OUT) of CN305, A

board.

5. Select SAJ 1 ‘SHU’ with

1

and

4

of the commander by

setting to Service Mode and adjust to VB1=VB2=VB3=VB4

with

3

and

6

.

5-3. PICTURE QUALITY ADJUSTMENTS

SUB COLOR ADJUSTMENT

1. Input a PAL color-bar.

2. Set to the following condition:

PICTURE 100%, BRIGHTNESS 50%, COLOR 50%

3. Connect an oscilloscope to pin

1

(B OUT) of CN305, A board.

4. Set to Service Mode and select SAJ 3 ‘SCL’ with

1

and

4

of the commander then adjust to VB2=VB3=VB4 with

3

and

6

.

5. Press

[MUTING]

→

-

of the commander to write the data.

6. Adjust SAJ 3 ‘SCL’ as step 2 to 5 when receiving NTSC

color-bar.

6. Press

[MUTING]

→

-

of the commander to write the data.

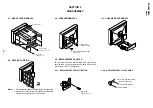

5-6. A BOARD ADJUSTMENT AFTER IC003

(MEMORY) REPLACEMENT

1. Enter to Service Mode.

2. Press commander buttons

5

and

-

(Data Initialize), and

2

and

-

(Data Copy) to initialize the data.

3. Call each item number and check if the respective screen

shows the normal picture.

In cases where items are not well adjusted, rectify the items

with fine adjustment.

Write the data per each item number (

[MUTING]

+

-

).

4. Select item numbers “OPB0” (OP1), “OPB1” (OP2),

“OPB2” (OP3), “OPB3” (OP4) and respectively set the bit

per model with command buttons

3

and

6

.

5. Press commander buttons

8

and

-

(Test Normal) to return

to the data that was set on the shipment from the factory.

(This will also cancel Service Mode.)

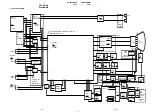

5-4. DEFLECTION ADJUSTMENT

1.

Set to Service Mode.

2.

Input PAL color bar.

3.

Using the

1

and

4

button, select category GEO

(Service Mode).

4.

Raise/lower the data using the

3

and

6

buttons.

Select and adjust the following items to obtain optimum

image.

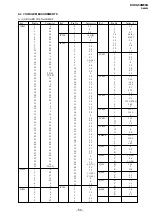

VB1

VB2

VB3

VB4

VB2 = VB3 = VB4

VB2 = VB3 = VB4 (Difference is within 70mV)

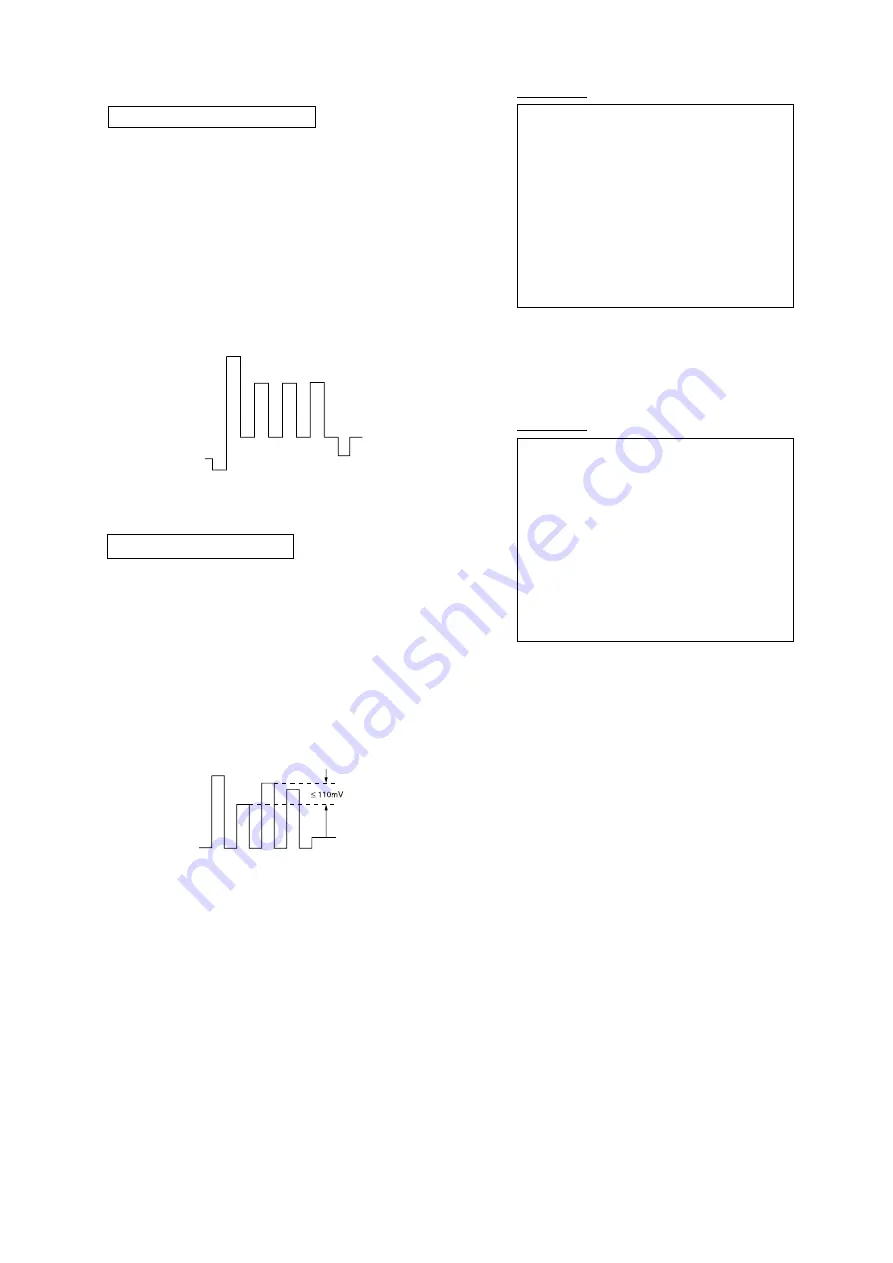

VB1

VB2

VB3

VB4

VB1 = VB2 = VB3 = VB4

The highest level of VB1,VB2,VB3,VB4 must be aligned at

the same line. Ideal difference level between VB2 and VB3

should be within ± 110mV.

Service Item

GEO : 00

HPS

H POSITION

01

HSZ

H SIZE

02

PAP

PIN AMP

03

TLT

TILT

04

VPS

V POSITION

05

VSZ

V SIZE

06

SCO

S CORRECTION

07

VLN

V LINEARITY

08

BOW AFC BOW

09

AGL

AFC ANGLE

0A

UPN

UPPER CORNER PIN

0B

LPN

LOWER CORNER PIN

5.

Input 525/60Hz signal.

6.

Using the

1

and

4

button select category GEO

(Service Mode).

7.

Select and adjust the following items to obtain optimum

image. Raise/lower the data with the

3

and

6

buttons.

Service Item

GEO : 00

HPS

H POSITION

01

HSZ

H SIZE

02

PAP

PIN AMP

03

TLT

TILT

04

VPS

V POSITION

05

VSZ

V SIZE

06

SCO

S CORRECTION

07

VLN

V LINEARITY

08

BOW AFC BOW

09

AGL

AFC ANGLE

0A

UPN

UPPER CORNER PIN

0B

LPN

LOWER CORNER PIN

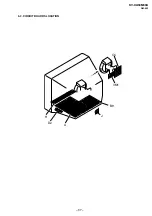

5-5. H-TRAPEZOID ADJUSTMENT

1. Receive cross hatch/dot signal.

2. Adjust RV1801 on C6 board to make H-trapezoid distortion

best.