1-4 (E)

UY

A-S90SF

6

(GB)

Mounting the Auto Slide Feeder on the Film

Scanner

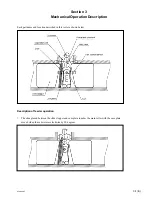

When you want to prescan/scan multiple slides continuously, mount the

supplied auto slide feeder on the film scanner.

Note

The mounting should be performed on a rigid, flat surface such as on a

desk, as the screw on the auto slide feeder cannot support the weight of the

auto slide feeder.

Install the film scanner on a base which covers the auto slide feeder.

1

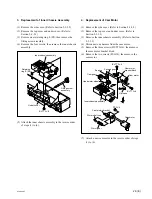

Remove the side panel of the film scanner and the cover of the slide

feeder connector.

2

Mount the auto slide feeder on the film scanner.

Insert the two projections on the rear of the auto slide feeder into the

slits on the film scanner, and the connector to the slide feeder

connector.

For easier positioning, place the auto slide feeder parallel to the side of

the film scanner, then fit the square projected part of the auto slide

feeder to the film scanner as illustrated.

Insert the projections.

Insert the

connector.

7

(GB)

3

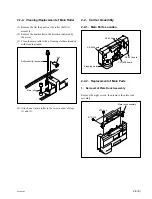

Tighten the screw to secure the auto slide feeder.

Note

To avoid damaging the screw of the auto slide feeder, do not tighten it

excessively.