2-5.

Outside Panel

2-5-1.

Outside Panel Assembly

Preparation

1.

Remove the battery lid. (Refer to

2.

Remove the bottom cover. (Refer to

“2-3. Bottom Cover and Tripod Washer”

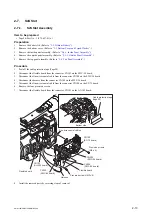

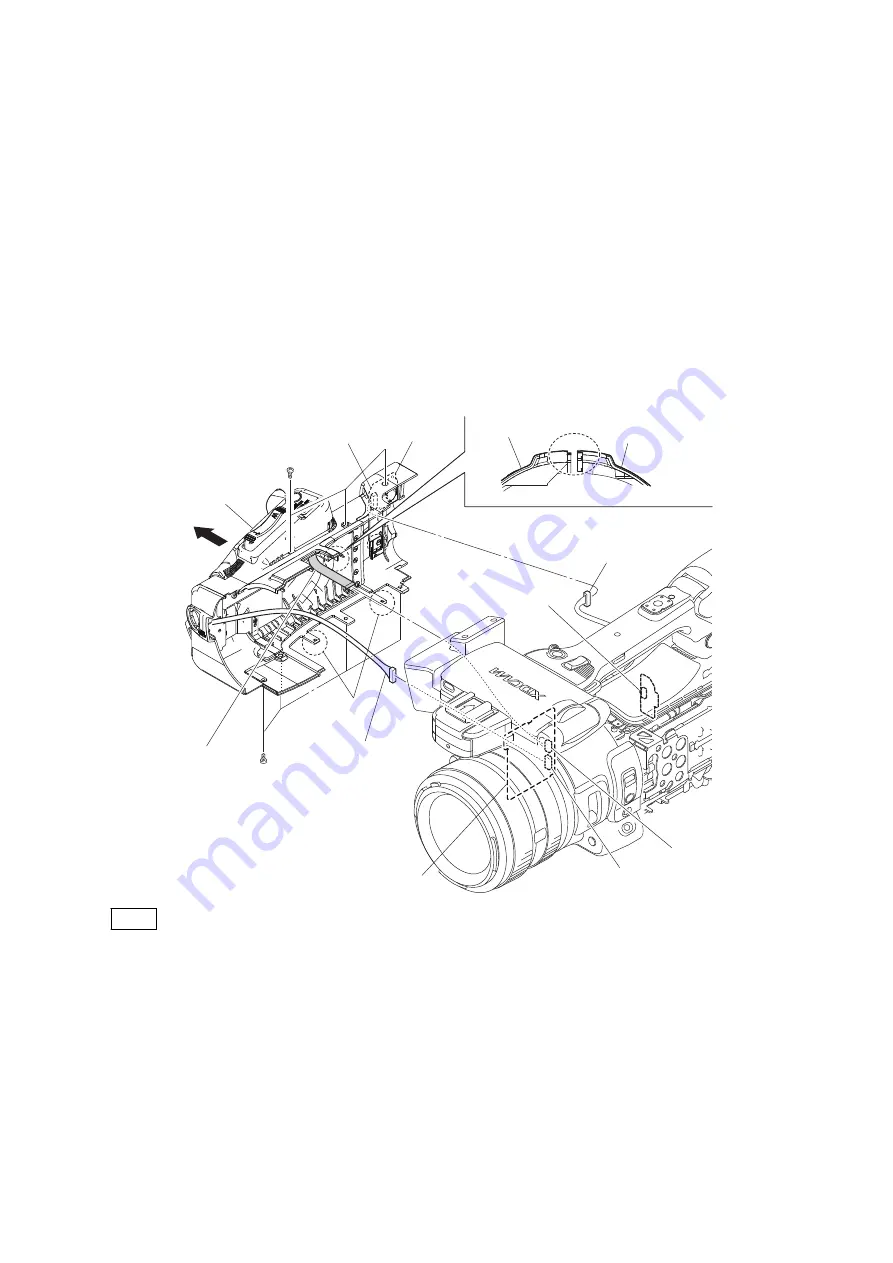

Procedure

1.

Remove the seven precision screws.

2.

Remove the two claws and remove the outside panel assembly in the arrow direction.

3.

Disconnect the harness from the connector CN100 on the IO-254 board.

4.

Disconnect the flexible flat cable and the harness from the two connector CN500, CN501 on the IFC-13 board to

detach the outside panel assembly.

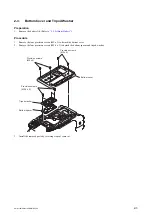

Inside panel

Outside

panel

Section of

engagement

IO-255 board

Slide switch (S100)

Harness

Claws

Flexible flat cable

Harness

Outside panel assembly

CN501

CN500

CN100

IFC-13 board

IO-254 board

Precision screws

(M2 x 5)

Precision screws

(M2 x 5)

Note

When installing the outside panel assembly, align the phase of the slide switch (S100) on the IO-255 board and the

knob of the outside panel assembly. At the section of engagement with the inside panel, install the outside panel

assembly so that the outside panel is under the inside panel.

5.

Install the removed parts by reversing steps of removal.

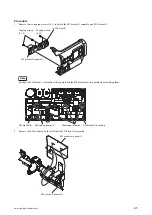

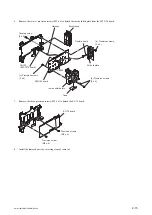

2-5-2.

Zoom Seesaw Assembly

Preparation

1.

Remove the battery lid. (Refer to

2.

Remove the bottom cover. (Refer to

“2-3. Bottom Cover and Tripod Washer”

.)

3.

Remove the outside panel assembly. (Refer to

“2-5-1. Outside Panel Assembly”

.)

PMW-160/PMW-150/PMW-EX260

2-9

Summary of Contents for XDCAM PMW-160

Page 1: ...SOLID STATE MEMORY CAMCORDER PMW 160 PMW 150 PMW EX260 SERVICE MANUAL 1st Edition ...

Page 4: ......

Page 8: ......

Page 10: ......

Page 30: ......

Page 38: ...3 Install the removed parts by reversing steps of removal PMW 160 PMW 150 PMW EX260 2 8 ...

Page 92: ......

Page 128: ......

Page 130: ......

Page 131: ......