9

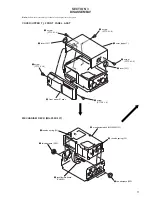

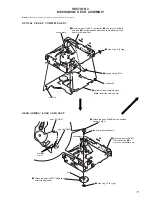

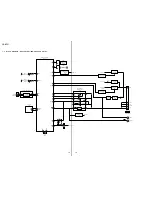

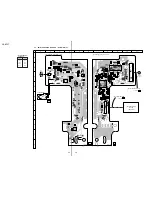

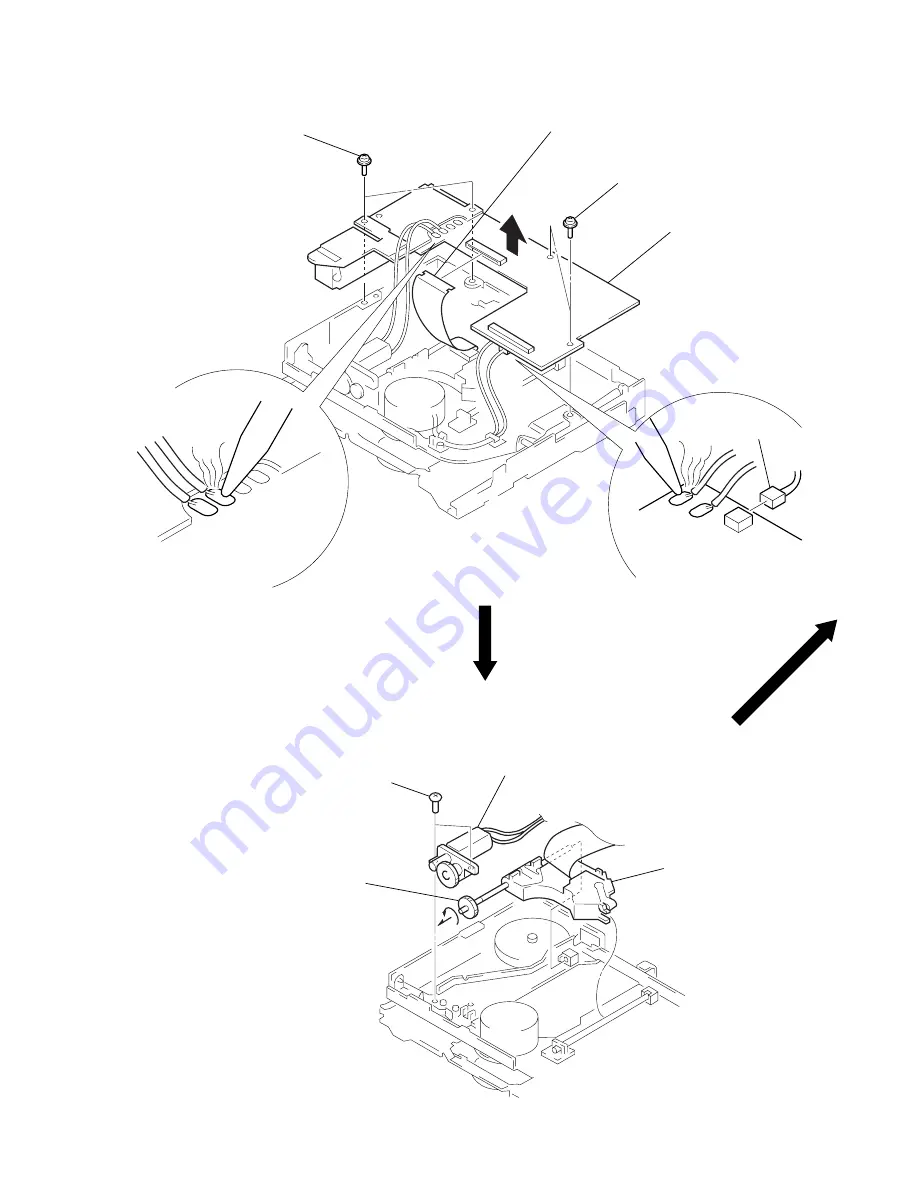

RF BOARD

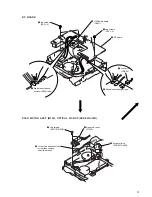

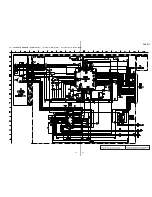

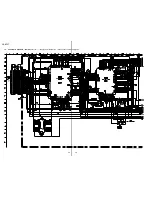

SLED MOTOR ASS’Y (M102), OPTICAL PICK-UP (KSS-521A/J2N)

4

3

two screws

(PS2

×

4)

5

connector

(CNP53)

7

RF board

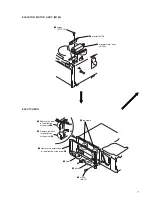

3

two screws

(PS2

×

4)

1

OP flexible board

(CNJ11)

2

Break the soldering

of motor (M102) lead.

6

Break the soldering of lead.

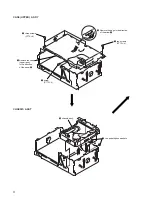

1

two screws

(ESCUTCHEON)

4

Turn at the direction of the

arrow, then remove

shaft (sled) ass’y

2

sled motor ass’y

(M102)

3

optical pick-up

(KSS-521A/J2N)

Summary of Contents for Xplod CDX-737

Page 4: ...4 4 ...