8

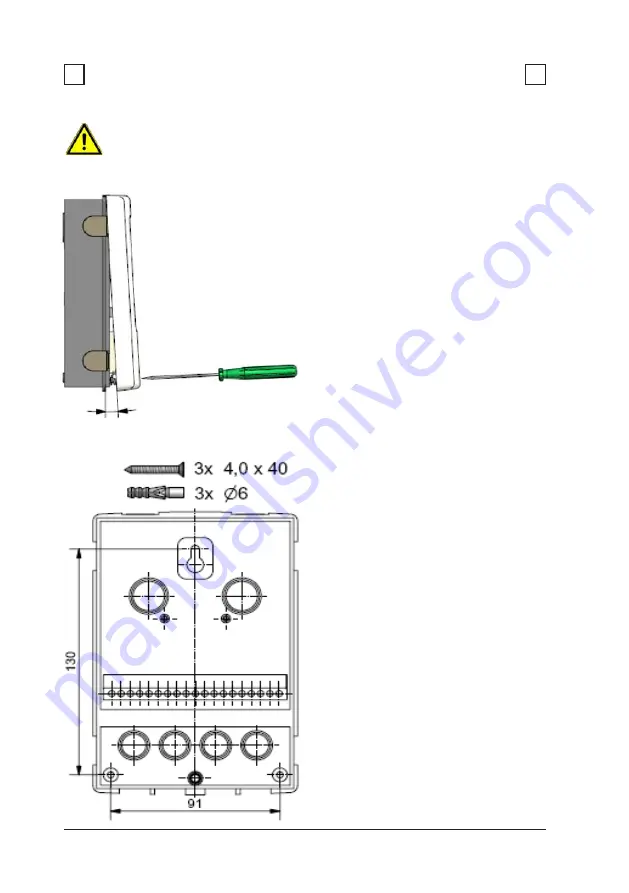

3.1 Wall installation

Installation

3

3

Caution

Install the controller only in dry areas and under the ambient

conditions described under 2.1 “Specifications

”

. Carry out the

following steps 1-8.

A

Fig.3.1.1

Fig.3.1.2

1.Unscrew cover screw completely

2.Carefully pull upper part of

housing from lower part.

3.Set upper part of housing aside,

being sure not to touch the

electronics when doing so.

4.Hold the lower part of the hous-

ing up to the selected position and

mark the 3 mounting holes.

Make sure that the wall surface is

as even as possible so that the

housing does not become

distorted when it is screwed on.

5.Using a drill and size 6 bit, drill

3 holes at the points marked

on the wall and push in the plugs.

6.Insert the upper screw and screw

it in slightly.

7.Fit the upper part of the housing

and insert the other two screws.

8. Align the housing and tighten the

three screws.

Summary of Contents for TDC 2

Page 35: ...35 Notes...