6.6

6.6 TRACK ALIGNMENT PROCEDURE

NOTICE

•

TORQUE BOLTS M24 AT 954NM (704 LB-FT)

•

TIGHTEN AGAIN AFTER 3 HOURS, 10 HOURS AND DAILY FOR THE FIRST WEEK OF

OPERATION OR UNTIL SET.

•

MAKE SURE THAT AFTER THE FINAL ALIGNMENT, RE-TIGHTEN THE 16 X M24 (3) SCREWS

ON THE TOP AND BOTTOM OF THE MAIN AXLE

1.

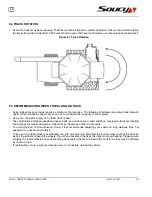

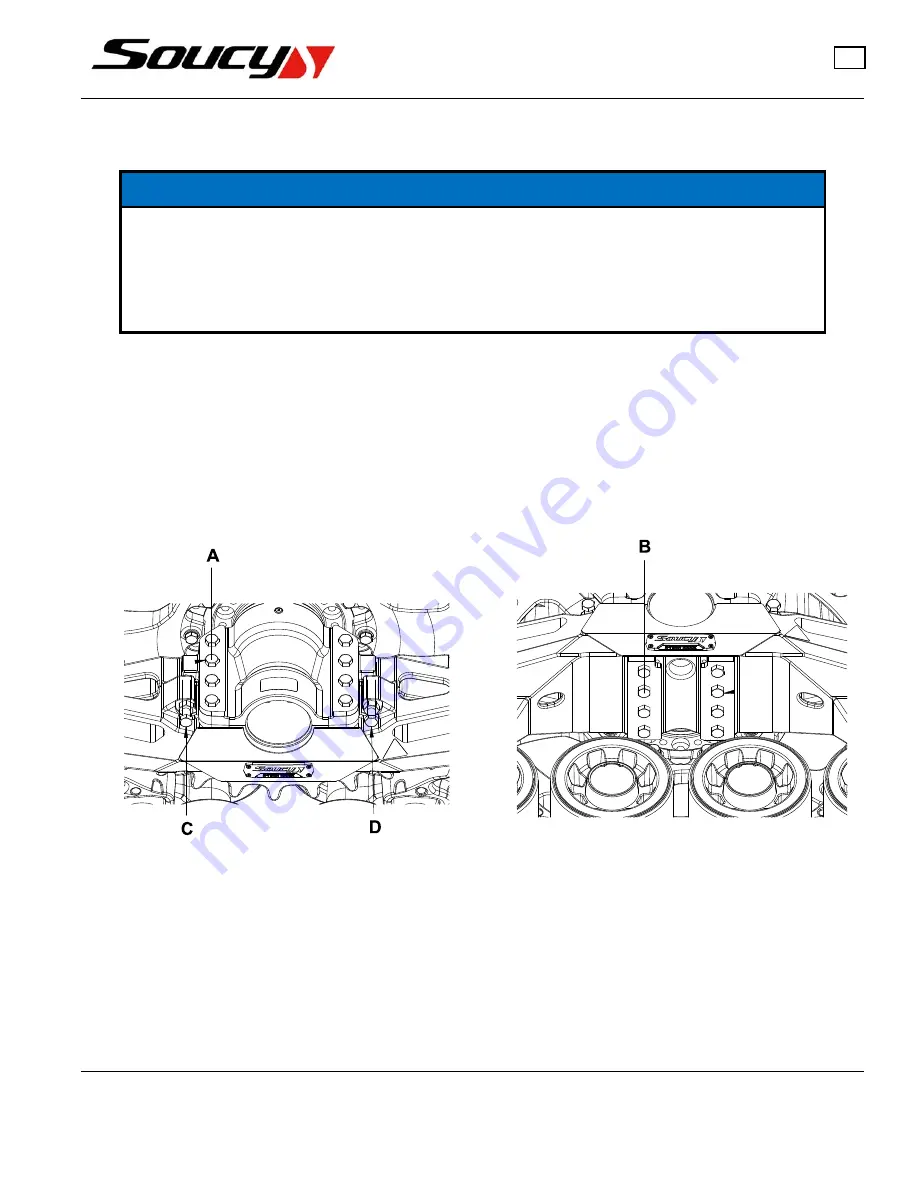

Make sure the combine is on a flat surface then loosen the 16 screws (A, B) on the top and bottom of the main axle.

See figure.

2.

. If the temperature of the drive lug is higher on the inner side, add toe-in. If the temperature of the drive lug is higher

on the outer side, add toe-out.

a.

To add toe-in, loosen the adjustment screw (C) by 1 full turn and tighten the rear adjustment screw (D) by 1 full

turn.

b.

To add toe-out, loosen the adjustment screw (D) by 1 full turn and tight the rear adjustment screw (C) by 1 full

turn.

3.

Tighten 16 x M24 screws (A, B) on the top and bottom main axle according to the TRACK ALIGNMENT

PROCEDURE (NOTICE).

SOUCY TRACK SYSTEMS USER GUIDE

A-8J1201-7-EN

47

Summary of Contents for S-TECH 1000X

Page 10: ...Page Intentionally Left Blank SOUCY TRACK SYSTEMS USER GUIDE A 8J1201 7 EN 6...

Page 14: ...Page Intentionally Left Blank SOUCY TRACK SYSTEMS USER GUIDE A 8J1201 7 EN 10...

Page 52: ...Page Intentionally Left Blank SOUCY TRACK SYSTEMS USER GUIDE A 8J1201 7 EN 48...

Page 68: ...Page Intentionally Left Blank SOUCY TRACK SYSTEMS USER GUIDE A 8J1201 7 EN 64...