5

1

/

4

” 6-32 machine

screw

Flush mount

cup

Mounting

surface

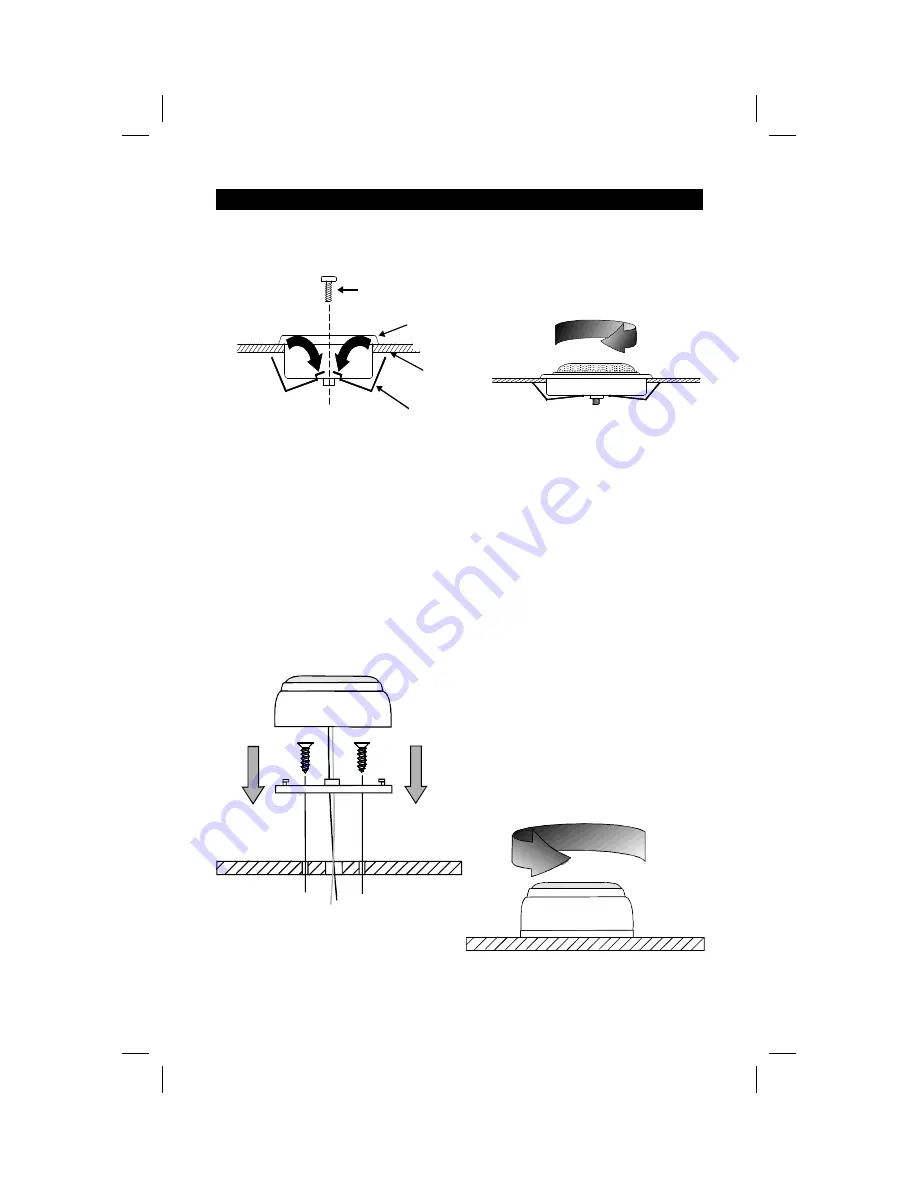

FIGURE 2

FIGURE 1

Spring

clip

Surface Mounting:

1) Drill one 5/16" diameter hole for the tweeter lead wires and two pilot

holes for the mounting screws.

2) Attach the surface mount plate with two flat head screws.

3) Pass the lead wires through the hole. See figure 3.

4) Engage the locking holes on the back of the tweeter onto the tabs on

the plate and rotate counter-clockwise until locked. See figure 4.

FIGURE 3

FIGURE 4

Turn Counter-Clockwise to Lock

Turn Clockwise to Lock

60.pub

page 5

Friday, September 10, 1999 21:03