32

MSH/MPH series

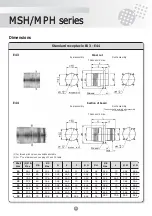

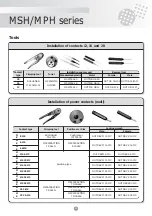

Wiring instructions gage 12, 16

and 20 contact connectors

• Use the crimping tool and positioner specified.

Adjust the positioner to the wire gage.

• Strip the wire to 7 mm.

• Insert the stripped end of the wire, placing the insulator against the rear

of the contact. Check that the conductor is visible through the contact

sight hole.

• Fully open the crimping tool.

• Insert the contact and the wire into the crimping tool.

• Fully close the crimping tool, and allow it to open.

• Check that the contact is correctly crimped. The wire must be visible

through the contact sight hole, and the wire insulator must be up

against the rear of the contact.

For crimping of coaxial contacts, depending on the cables used,

see the technical instructions supplied with each delivery of MS coaxial

connectors.

Stripping

A = “Sight hole” for checking the presence of the conductor before and

after crimping.

Installing and removing crimped contacts

• The use of plastic tools is recommended.

• The use of mechanical tools requires special care to avoid.

Plastic tools

Installation:

• Insert the wire into the channel on the plastic tool.

• Slide the tool along the wire to the stop on the contac shoulder.

Keep the wire taut so that the tool remains against the contact.

• Insert the contact into the housing from the rear of the connector, and

push the tool in as far as it will go, until the contact locks.

• Remove the tool.

• Pull gently on the wire to check that the contact is firmly attached.

Removal:

• Insert the wire into the channel on the plastic tool.

• Slide the tool along the wire so that it enters the connector insulator

and comes to a stop against the rear contact shoulder.

• Remove the tool and the contact at the same time.

• If there is any resistance before freeing the contact, move the tool

backwards, without removing it altogether, turn it slightly, and put it

back in.

Metal contacts

Installation

Insert the contacts into the insulator from the rear by pushing them

in using tool OUT-MB-DB, with the part number corresponding to the

gage of the contact used (fig. 5). This tool must be aligned such that

its XX axis is parallel with the marking on the insulator (fig. 2).

It is recommended that the assembly tool be lubricated before each use.

• If slight resistance encountered, do not force the tool, but check that it

is perpendicular to the plane of the insulator.

• Never turn the tool in the insulator.

Insert the tool OUT.MB.DB appropriate to the contact gage from the rear,

aligned such that its YY axis is perpendicular to the marking on the insu-

lator (fig. 5), in order to free the contact. Once this tool is in place, with

its opening always pointing down in relation to the number, push the

contact out using the corresponding OUT.DB tool.

Note :

the same care should be taken as with installation of contacts.

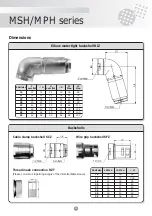

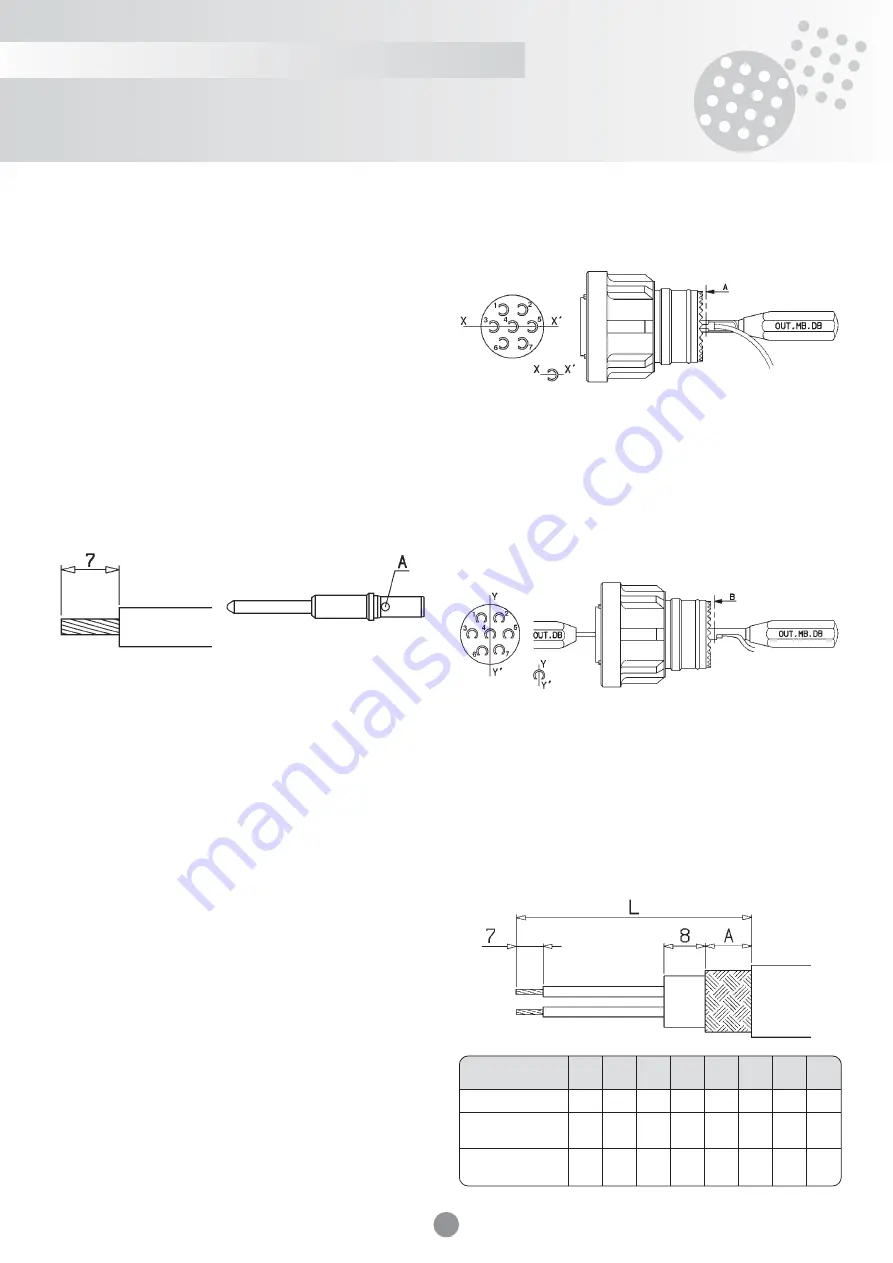

Cable stripping

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Shell size

16

17

18

20

22

24

26

28

a

10

10

10

10

10

10

13

15

Straight

backshell L

56

61

71

76

84

89

96

96

Elbow

backshell L

79

94

109

119

134

144

154 169