South Bend Tools

For Machines Mfd. Since 12/21

Model SB1007

-45-

O P E R A T I O N

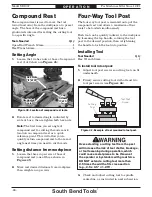

Setting Power Feed Rate of 0.0018 in./rev.:

1.

Make sure end gears are in configuration

indicated on feed rate chart (refer to End

Gears on this page for detailed instructions).

2.

Locate box on feed rate chart that lists

setting for 0.0018" of feed per revolution of

spindle.

3.

Rotate quick-change gearbox knobs to alpha-

numeric settings indicated on feed rate chart

(in this instance, 1A).

4.

Use headstock feed direction lever to select

direction of carriage travel.

When lever is to the left, carriage will move

toward the spindle. Conversely, when lever

is to the right, the carriage will move away

from the spindle.

5

. Shift feed selection lever up to select carriage

for power feed.

To prevent damage to gearbox components,

NEVER move levers while lathe is running,

and NEVER force any lever when shifting. If

lever will not engage, rotate chuck by hand

while keeping light pressure on the lever. As

chuck rotates, it aligns the gears and the lever

will engage.

End Gears

The end gears on this lathe can be configured

according to the operation to be performed:

power feed and inch or metric threading. The

operation you choose will determine which

gear configuration you must use. This includes

the number of gears—either three or four—

and the tooth count of each gear. The SB1007

lathe arrives from the factory in the three-gear

configuration.

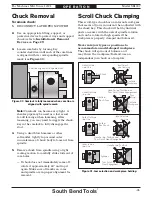

The figure below shows the location of each

component that must be considered when

changing gears. The configuration of the gears is

specified on the feed rate and threading charts.

Tools Needed

Qty

Hex Wrench 5mm .................................................1

Hex Wrench 6mm .................................................1

Open-End Wrench 13mm .....................................1

To install three-gear configuration:

1.

DISCONNECT LATHE FROM POWER!

2.

Remove headstock end gear cover.

3.

Loosen support arm cap screw (see Figure

61) and allow assembly to pivot down.

4

. Install top and bottom gears indicated by

feed rate or threading charts. Make sure

keys stay inserted in shafts when removing

these gears.

Figure

Figure 61. End gear support arm and components.

. End gear support arm and components.

Bottom

Bottom

Gear

Gear

Top Gear

Top Gear

Support Arm

Support Arm

Cap Screw

Cap Screw

Lower Slot

Lower Slot

Upper Slot

Upper Slot