South Bend Tools

For Machines Mfd. Since 12/21

Model SB1007

-61-

S E R V I C E

4.

Ensure belt teeth are properly engaged in

pulley notches, push down on motor with

light/moderate pressure, and tighten motor

mount hex bolts.

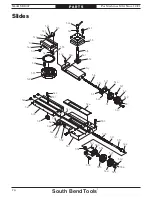

The timing belt is correctly tensioned when

there is approximately

1

⁄

8

" deflection when it

is pushed with moderate pressure, as shown

in Figure 94.

5.

When deflection is correct, retighten motor

mount hex bolts.

6.

Re-install end gear cover.

Replacing Belt:

1.

DISCONNECT

LATHE FROM POWER!

2.

Remove

end gear cover.

3.

Loosen four motor mount hex bolts (see

Figure 93 on previous page), slide motor up,

and remove belt.

Note:

Loose pulleys impact transmission

of power from motor. If pulleys are loose,

retighten them now.

4.

Slide off old timing belt and install new

one, making sure that belt teeth are seated

together with pulley teeth.

5.

Tension belt (see Figure 95), then retighten

motor mount bolts.

6. Re-install end gear cover.

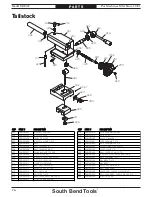

Figure

Figure 95. Timing belt properly seated with pulley.

. Timing belt properly seated with pulley.

Timing

Timing

Belt

Belt

Pulley

Deflection

Pulley

Figure

Figure 94. Correct belt deflection.

. Correct belt deflection.

1

⁄

8

"