South Bend Tools

For Machines Mfd. Since 12/21

Model SB1007

-37-

O P E R A T I O N

9.

Repeat

Steps 6–8 until desired accuracy is

achieved.

Move the tailstock toward

the

front of the lathe ½ the

distance of the taper.

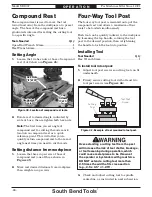

Looking down from above.

Figure

Figure 42. Adjust tailstock toward front of lathe.

. Adjust tailstock toward front of lathe.

— If test stock is thinner at tailstock end,

move tailstock toward the back of lathe

1

⁄

2

distance of amount of taper (see Figure

43).

Move tailstock toward the

back of the lathe ½ the

distance of the taper.

Looking down from above.

Figure

Figure 43. Adjust tailstock toward back of lathe.

. Adjust tailstock toward back of lathe.

— If test stock is thicker at tailstock end,

move tailstock toward the front of lathe

1

⁄

2

distance of amount of taper (see Figure

42).

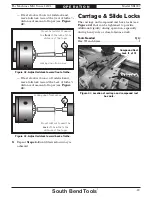

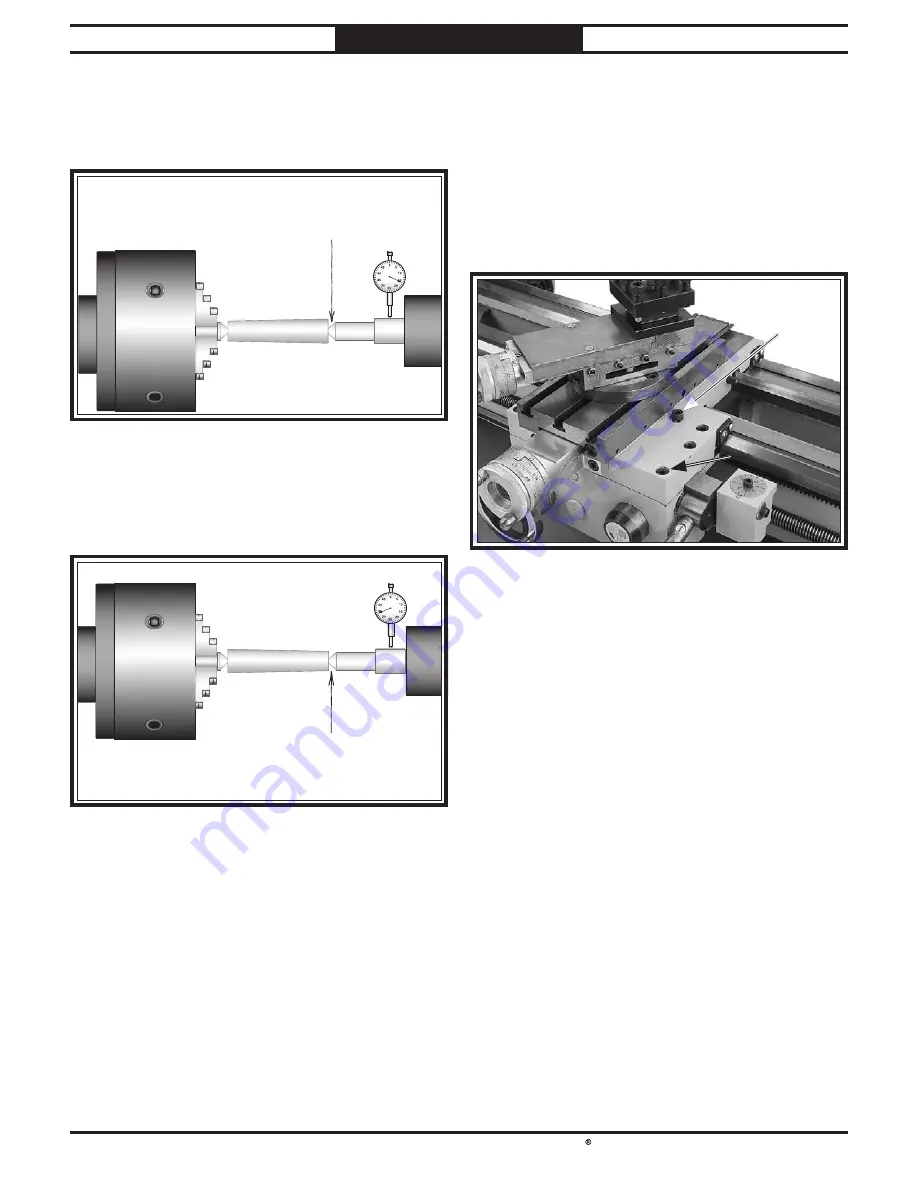

Carriage & Slide Locks

The carriage and compound rest have locks (see

Figure 44) that can be tightened to provide

additional rigidity during operation, especially

during heavy cuts or close tolerance work.

Tools Needed

Qty

Hex Wrench 6mm .................................................1

Figure

Figure 44. Location of carriage and compound rest

. Location of carriage and compound rest

hex nuts.

hex nuts.

Compound Rest

Compound Rest

Lock (1 of 3)

Lock (1 of 3)

Carriage Lock

Carriage Lock