South Bend Tools

For Machines Mfd. Since 11/20

Model SB1099

-41-

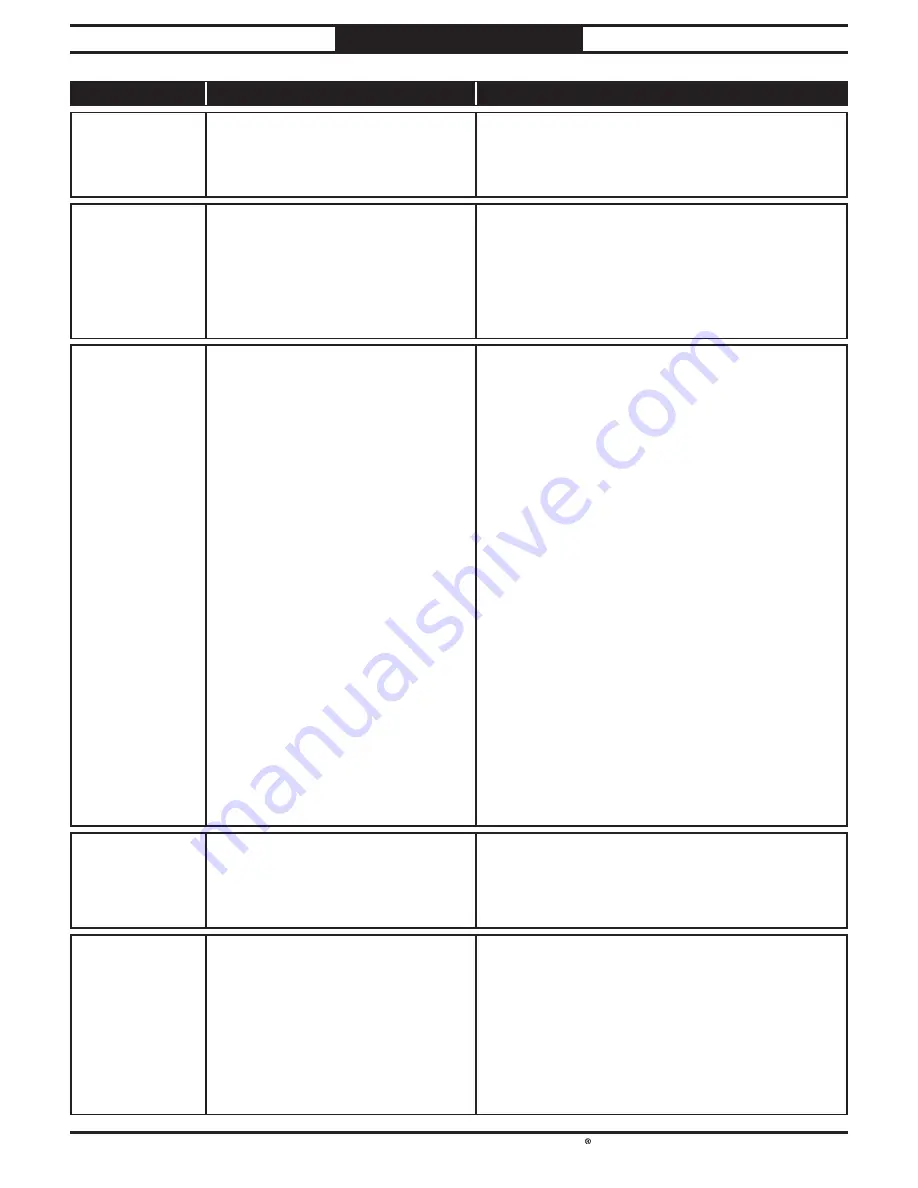

TROUBLESHOOTING

Symptom

Possible Cause

Possible Solution

Remote control

does not operate

dust collector.

1.

Emergency Stop button is pressed in.

1.

Rotate Emergency Stop button to reset.

2.

Machine is disconnected from

power.

2.

Verify machine is connected to power source.

3.

Remote control battery is weak or

dead.

3.

Replace battery.

4.

Wall or barrier disrupts radio

frequency, or controller is too far

away.

4.

Move machine away from barrier; use remote

within 50' of machine.

5.

Remote control not paired.

5.

Program receiver to accept remote control (Page 39).

Dust collector

blows sawdust into

the air.

1.

Duct clamps or end cap not properly

clamped and secured; ducting loose/

damaged.

1.

Secure ducts and end cap, making sure duct and

bag clamp are tight; tighten/replace ducting.

2.

Cylinder or funnel seals are loose or

damaged.

2.

Tighten all mounting and sealing points; replace

damaged seals/gaskets or use silicon to seal.

Loud, repetitious

noise, or excessive

vibration coming

from dust collector

(non-motor

related).

1.

Dust collector not on a flat surface

and wobbles/casters not locked.

1.

Stabilize dust collector; lock casters.

2.

Impeller damaged and unbalanced.

2.

Disconnect dust collector from power; inspect

impeller for dents, bends, or loose fins; replace

impeller if damaged.

3.

Impeller loose on the motor shaft.

3.

Secure impeller; replace motor and impeller as a set

if motor shaft and impeller hub are damaged.

Filter brush motor

does not start after

machine is powered

OFF.

1.

Motor connected incorrectly at

switch box.

1.

Correct motor wiring connections (Page 43).

2.

Timer at fault.

2.

Inspect/replace if at fault.

3.

Filter brush motor at fault.

3.

Replace motor.

Dust collector does

not adequately

collect dust

or chips; poor

performance.

1.

Collection bag/end cap full.

1.

Replace collection bag (Page 35)/empty end cap

(Page 36).

2.

Canister filter clogged/at fault.

2.

Clean canister filter (Page 36); replace canister

filter after 1 year of regular use (Page 37).

3.

Ducting blocked/restricted.

3.

Remove ducting from dust collector inlet and

unblock restriction. A plumbing snake may be

necessary.

4.

Dust collector too far away from

point of suction; duct clamps not

properly secured; too many sharp

bends in ducting.

4.

Relocate dust collector closer to point of suction; re-

secure ducts; remove sharp bends (Page 22).

5.

Lumber is wet and dust is not

flowing smoothly through ducting.

5.

Only process lumber with less than 20% moisture

content.

6.

Ducting has one or more leaks, or

too many open ports.

6.

Seal/eliminate all ducting leaks; close dust ports for

lines not being used (Page 22).

7.

Not enough open branch lines at

one time, causing velocity drop in

main line.

7.

Open 1 or 2 more blast gates to different branch

lines to increase main line velocity.

8.

Ducting and ports are incorrectly

sized.

8.

Install correctly sized ducts and fittings (Page 22).

9.

Machine dust-collection design

inadequate.

9.

Use dust-collection hood on stand.

10.

Dust collector undersized.

10.

Install larger dust collector.

11.

Unused inlet adapter port(s)

uncovered.

11.

Cover unused inlet adapter port(s).