South Bend Tools

For Machines Mfd. Since 12/21

Model SB1102

-35-

S E R V I C E

Items Needed:

Qty

Open-End Wrench 19mm .....................................1

Phillips Screwdriver #2 ........................................1

To adjust conveyor belt tension and tracking:

1.

Turn machine ON and observe conveyor belt

tension and tracking. Be patient, belt tracks

slowly.

2.

DISCONNECT MACHINE FROM POWER!

3.

Remove roller bracket guards.

Always make conveyor belt adjustments at

infeed end to avoid re-adjusting conveyor

drive chain. Conveyor belt tracking

adjustments must be made while the

conveyor belt is running. Use extreme care

to ensure that clothing, hair or jewelry is

kept safely away from moving parts.

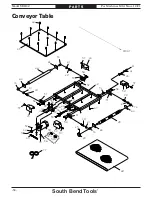

The conveyor belt tension and tracking

adjustments are controlled by the adjustment

bolts located at each end of the front and rear

conveyor rollers. If the conveyor belt is too loose

or tracks off to one side, it must be adjusted.

Adjusting Conveyor

Belt Tension &

Tracking

1.

DISCONNECT MACHINE FROM POWER!

2.

With gauge block in place on one side of

table, adjust table to

Reference Height #1

(refer to

Page 32

).

3.

Lower table one full turn of handwheel .

4.

On same side as gauge block, loosen

jam nuts on roller height hex bolts (see

Figure 44

).

To adjust pressure roller height:

5.

Adjust all (3) pressure rollers by tightening

or loosening hex bolts. The pressure rollers

should just touch surface of gauge block,

allowing enough room to rotate.

6.

Tighten jam nuts on hex bolts to secure

height position.

7.

Repeat

Steps 2–6 on other side of table to

make sure all pressure rollers are even and

parallel to table.

Note:

These adjustments should be used as a

starting point. Once you are familiar with the

adjustment process, you should experiment

to determine the best settings for your specific

application.

Figure 44. Location of pressure roller height

Figure 44. Location of pressure roller height

adjustment bolts (right side shown).

adjustment bolts (right side shown).

!