-36-

For Machines Mfd. Since 12/21

South Bend Tools

Model SB1102

S E R V I C E

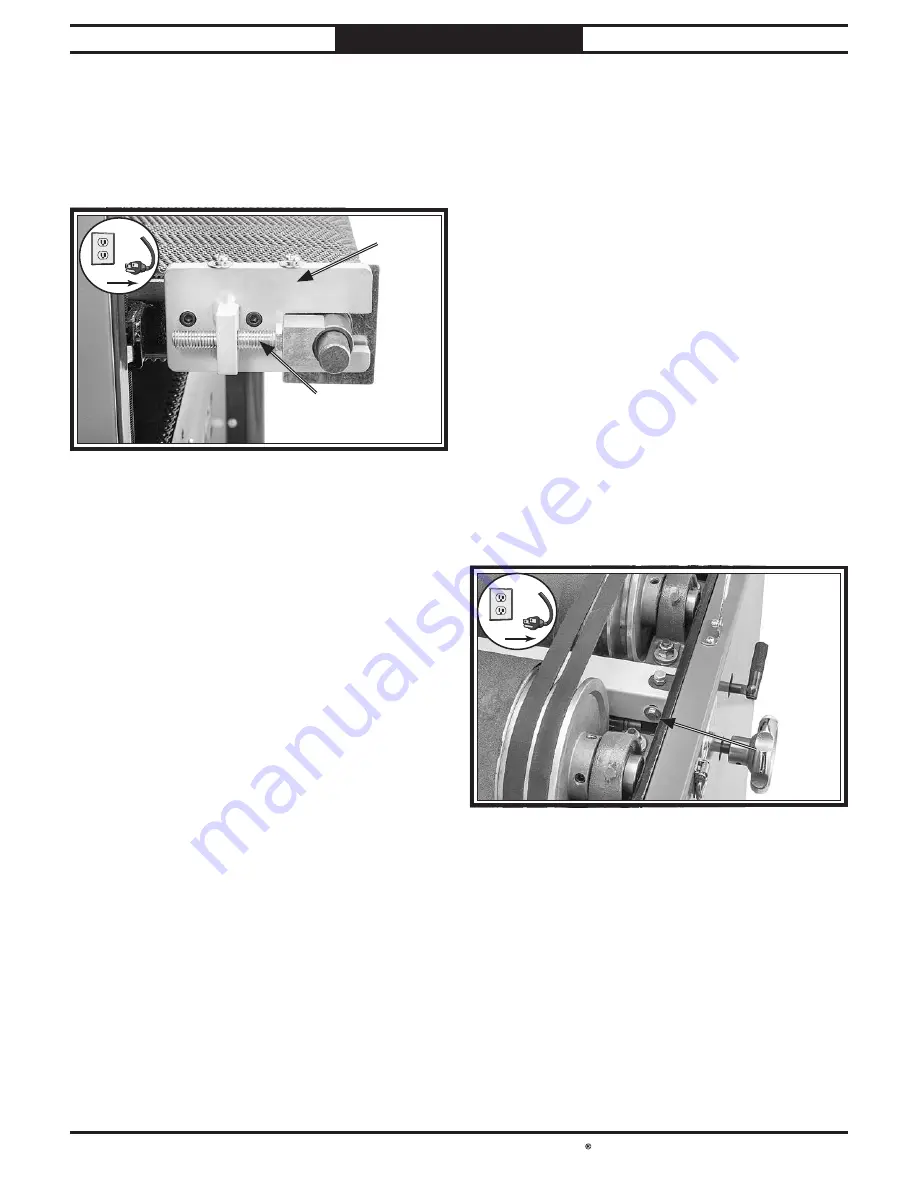

— If belt tracks toward right, rotate

right-side roller adjustment bolt

counterclockwise to move belt left.

— If belt tracks toward left, rotate right-side

roller adjustment bolt clockwise to move

belt right.

5.

After adjustments are made, run machine

for approximately 15 minutes to watch the

tension or tracking adjustments you made.

Be patient, belt tracks slowly.

6.

Re-install roller bracket guards.

4.

To make conveyor belt tension and tracking

adjustments, do the following:

— If belt slips on rollers, rotate both roller

adjustment bolts evenly (see Figure 45)

counterclockwise to increase belt tension.

Adjusting Dust Scoop

The Model SB1102 features a dust scoop for

each drum. Dust scoops reduce the amount of

dust that accumulates on the workpiece as it

travels through the sander. Dust scoops are

adjustable and should be set approximately

1

⁄

32

'' above the bottom of the drum for optimum

effectiveness.

Items Needed:

Qty

Open-End Wrench 10mm .....................................1

Gauge Blocks (2" x 4" x 24") .................................1

4.

Move scoop up or down until it is

approximately

1

⁄

32

'' above gauge blocks.

Some flexing of sheet metal assembly may

be needed to get the proper clearance.

Retighten the mounting bolts and remove

gauge blocks.

adjusting dust scoop

To adjust dust scoop:

1.

DISCONNECT MACHINE FROM POWER!

2.

Place (2) gauge blocks of equal height under

rear sanding drum and dust scoop. Raise

table until gauge blocks just touch sanding

drum.

3.

Loosen dust scoop mounting bolts located at

each end of scoop (see Figure 46).

Figure

Figure

46

. Location of dust scoop mounting bolts.

. Location of dust scoop mounting bolts.

Dust Scoop Mounting

Dust Scoop Mounting

Bolt (1 of 2)

Bolt (1 of 2)

!

Figure

Figure 45. Location of conveyor roller adjustment

. Location of conveyor roller adjustment

bolts.

bolts.

Roller Bracket

Roller Bracket

Roller Adjustment

Roller Adjustment

Bolt (1 of 2)

Bolt (1 of 2)

!