-38-

For Machines Mfd. Since 12/21

South Bend Tools

Model SB1102

S E R V I C E

Replace the V-belts if you notice fraying,

cracking, glazing, or any other damage. A worn/

damaged V-belt will not provide optimum power

transmission from the motor to the drums.

V-belt removal and replacement is simply a

matter of raising the motor and loosening the

V-belts until you can roll them off the pulleys,

replacing them with a MATCHED set, then re-

tensioning them. Always replace both belts at the

same time with a new matched set.

Note:

A matched set means both the V-belts are

the same size and also have the same belt type

number.

Belt Removal/Replacement

Pulley Alignment

Pulley alignment is another important factor in

power transmission and belt life. The pulleys

should be parallel to each other and in the same

plane (coplaner) for optimum performance.

Each pulley can be adjusted by loosening the set

screw that secures the pulley to the shaft, sliding

the pulley in/out, and retightening the set screw

to lock the pulley in place.

6.

Press down on motor to add tension to the

belt, then tighten motor mount hex bolts.

7.

Check V-belt tension (see

Figure 47 on

Page 37). If necessary, repeat Steps 4–5

until belts are properly tensioned, then

tighten hex bolts.

8.

Install right side panel, connect right side

support arm, and install handwheel and

micro-adjustment knob.

1.

DISCONNECT MACHINE FROM POWER!

2.

Perform Steps 1–5 of Belt Tension on

Page 37, then remove V-belts.

3.

Place straightedge across face of motor

pulley and front drum pulley to check

alignment. The straightedge should sit

evenly on top and bottom part of both

pulleys.

4.

Repeat Step 3 with straightedge placed

against motor pulley and rear drum pulley.

5.

Loosen pulleys and adjust them as necessary

until they are all coplanar with each other,

and then tighten set screws.

6.

Install and properly tension V-belts, tighten

motor mount fasteners.

7.

Install side cover, connect right side support

arm, and install handwheel and micro-

adjustment knob.

Belts and pulleys will be hot after operation.

Allow them to cool before handling.

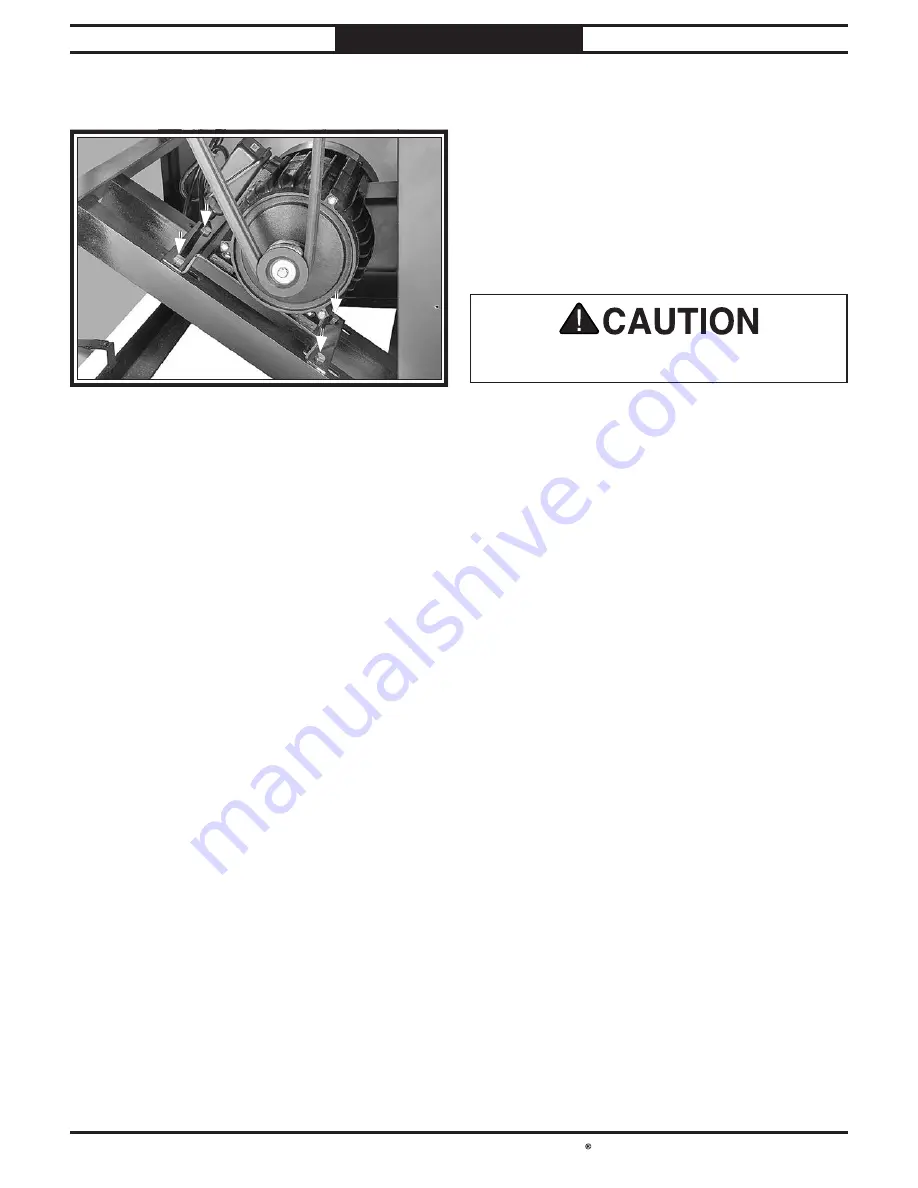

5.

Loosen (4) motor mount hex bolts as shown

in Figure 50. DO NOT remove bolts!

Figure 50. Locations of motor mount bolts.

Figure 50. Locations of motor mount bolts.

Motor Mount

Motor Mount

Hex Bolts (4)

Hex Bolts (4)

To align pulleys: