South Bend Tools

For Machines Mfd. Since 12/21

Model SB1102

-15-

P R E P A R A T I O N

4.

Apply

1

⁄

16

" double sided tape to bottom

perimeter of each dust port, then attach to

dust hood as shown in Figure 10.

5.

Secure dust ports to dust hood with

(8) #8 x

1

⁄

2

" tap screws and (8) #8 flat

washers.

3.

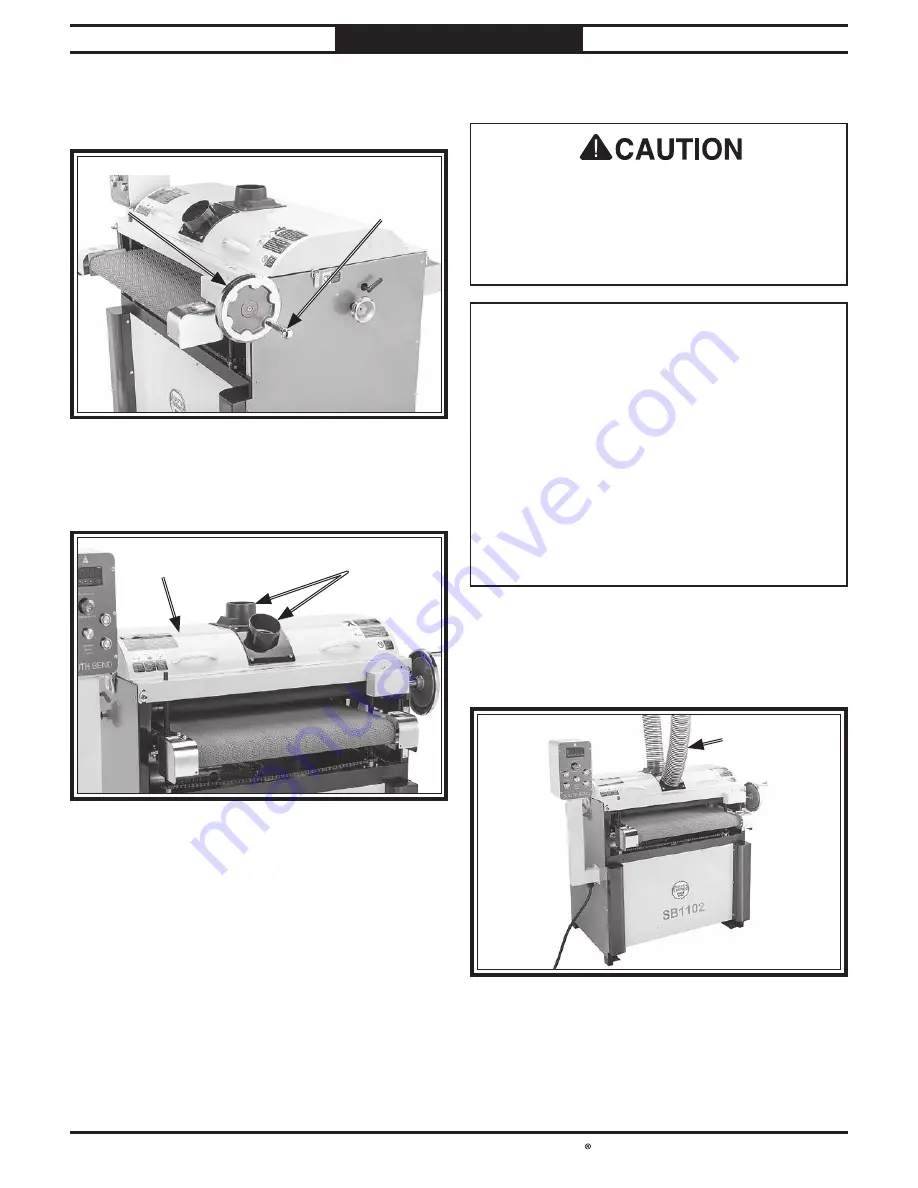

Attach handwheel to spindle and tighten

pre-installed set screw, then attach

handwheel handle (see Figure 9).

Dust Collection

1.

Fit (2) 4" dust hoses over dust ports as

shown in Figure 11 and secure in place with

(2) hose clamps.

Minimum CFM at each Dust Port: 400 CFM

Do not confuse this CFM recommendation

with the rating of the dust collector. To

determine the CFM at the dust port, you

must consider these variables: (1) CFM

rating of the dust collector, (2) hose type

and length between the dust collector and

the machine, (3) number of branches or

wyes, and (4) amount of other open lines

throughout the system. Explaining how

to calculate these variables is beyond the

scope of this manual. Consult an expert or

purchase a good dust collection "how-to"

book.

This machine creates a lot of wood chips/

dust during operation. Breathing airborne dust

on a regular basis can result in permanent

respiratory illness. Reduce your risk by

wearing a respirator and capturing the dust

with a dust-collection system.

2.

Tug hoses to make sure they do not come

off. A tight fit is necessary for proper

performance.

To connect machine to dust collect system:

Figure

Figure 10. Dust ports attached to dust hood.

. Dust ports attached to dust hood.

4" Dust Ports

4" Dust Ports

Dust hood

Dust hood

Figure

Figure 11. Dust hoses attached.

. Dust hoses attached.

4" Dust Hose

4" Dust Hose

Figure 9. Handwheel and handle attached.

Figure 9. Handwheel and handle attached.

Handwheel

Handwheel

Handle

Handle

Handwheel

Handwheel