South Bend Tools

For Machines Mfd. Since 12/21

Model SB1102

-39-

S E R V I C E

Replacing Bearings

5.

Loosen (2) bearing set screws, as shown in

Figure 52, then remove bearing and bearing

block from drum spindle.

4.

Carefully lift drum up and out of the

machine and place on flat, stable surface.

The Model SB1102 is designed for many years of

reliable service. But after long periods of heavy

use, it may be necessary to replace the pillow

block bearings. Always replace both bearings on

the same drum at the same time.

Items Needed:

Qty

Cartridge Bearing (PSB1102081)....... 2 Per Drum

T26419 or NLGI#2 Equivalent ............. As Needed

Wrench or Socket 9/16" .........................................1

Hex Wrench 3mm .................................................1

Shop Rags .............................................. As Needed

replace drum bearings

To replace bearings:

1.

DISCONNECT MACHINE FROM POWER!

2.

Follow Steps to remove drive belts (see Belt

Tension on Page 37).

3.

Remove lock nut and flat washer from

bearing block assembly on each side of drum

(see Figure 51).

Figure

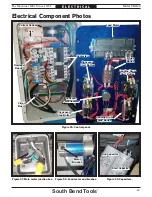

Figure 51. Bearing block lock nut locations.

Bearing block lock nut locations.

Bearing Block

Bearing Block

Lock Nuts

Lock Nuts

!

DO NOT hammer on the bearing or housing as

you WILL damage these precision parts.

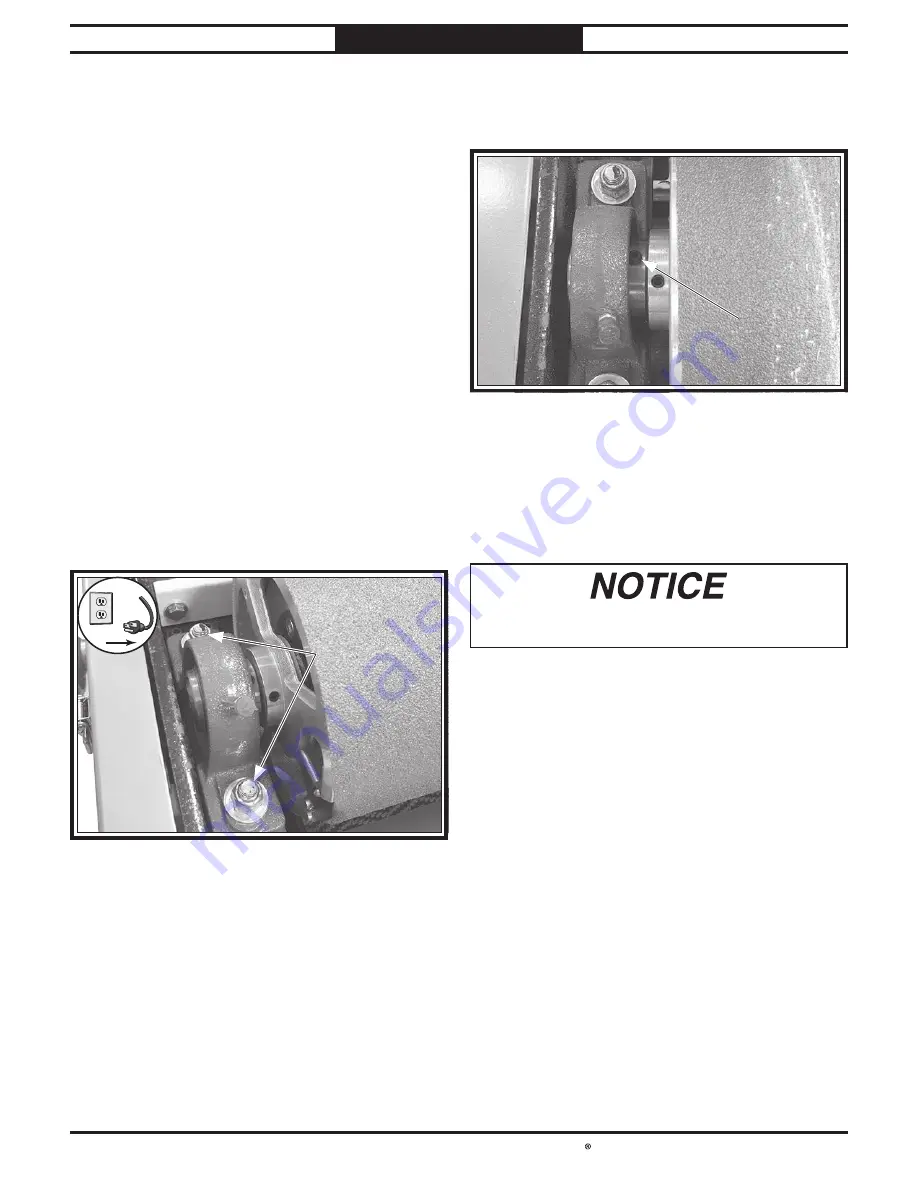

Bearing Set Screw

(1 of 2)

Figure 52. Location of bearing set screw.

6.

Clean and inspect drum spindle for damage

or unusual wear.

7.

Slide new bearing and bearing block into

place on the drum shaft. Do not tighten set

screws until next step.

8.

Install drum to mounting blocks, then

tighten bearing set screws.

9.

Follow steps for Aligning Drums shown on

Page 30.

10.

Install belts and follow steps for Belt

Tension on Page 37).

11.

Install side cover, connect right side support

arm, and install handwheel and micro-

adjustment knob.