For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

-19-

P R E P A R A T I O N

Leveling & Mounting

Leveling

Figure 9. Example of a precision level.

Leveling machinery helps precision components,

such as bed ways, remain straight and flat

during the lifespan of the machine. Components

on an unleveled machine may slowly twist due to

the dynamic loads placed on the machine during

operation.

For best results, use a precision level that

is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level.

See the figure below for an example of a high

precision level.

This machine and its parts

are heavy! Serious personal

injury may occur if safe

moving methods are not

used. To reduce the risk of a

lifting or dropping injury, ask

others for help.

Mounting

The base of this lathe has mounting four holes

that allow it to be secured to a workbench

or stand to prevent it from moving during

operation. The mounting holes are 5

1

⁄

4

" x 29

1

⁄

2

"

apart, center-to-center, and accept

3

⁄

8

" fasteners.

To help dampen vibration, place the rubber

mounting gasket between the workbench and the

lathe before installing the fasteners.

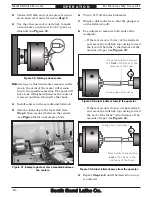

The strongest mounting option is a "Through

Mount" (see example in Figure 10) where holes

are drilled all the way through the workbench—

and hex bolts, washers, and hex nuts are used to

secure the machine in place.

Figure 10. Example of a "Through Mount" setup.

Machine Base

Workbench

Lag Screw

Flat Washer

Another option is a "Direct Mount" (see example

in Figure 11) where the machine is secured

directly to the workbench with lag screws and

washers.

Figure 11. Example of a "Direct Mount" setup.

Machine Base

Workbench

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut