-40-

For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

O P E R A T I O N

Note:

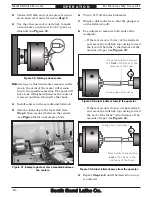

As you tighten the tensioning bolt, the

shafts will straighten and apply more

tension to the belts. The correct amount of

belt tension is when there is approximately

1

⁄

4

"–

3

⁄

8

" deflection with moderate pressure

applied to the belt between the pulleys (see

Figure 50).

Important:

Do not overtighten the belts—this

could cause the machine to run hot and

cause damage to the motor and bearings.

Figure 50. Testing for correct drive belt tension.

Pulley

Deflection

Pulley

Selecting Spindle Speed

When spindle rotation is started with the spindle

switch, the spindle speed is selected by rotating

the spindle speed dial (see Figure 51) until the

tachometer display shows the desired spindle

speed.

Figure 51. Spindle speed controls.

Spindle

Speed

Dial

Tachometer

Display

Power Feed &

Threading Setup

Timing Belts & Pulleys

The rate that the carriage moves when engaged

with the longitudinal leadscrew for power feed

or threading operations is controlled by the

configuration of the timing belts and pulleys (see

Figure 52).

Figure 52. Timing belt and pulley.

Timing

Belt

Pulley

The timing belt and pulley configurations for

the available feed rate and threading options

are displayed in the chart on the front of the end

cover (see Figure 53).

Figure 53. Feed rate and threading chart.

Feed Rate

& Threading

Chart

The maximum recommended spindle speed is

2300 RPM. DO NOT exceed this for more than

a brief period of time or machine damage may

occur.