For Machines Mfg. Since 7/09

Model SB1016/SB1036

-79-

S E R V I C E

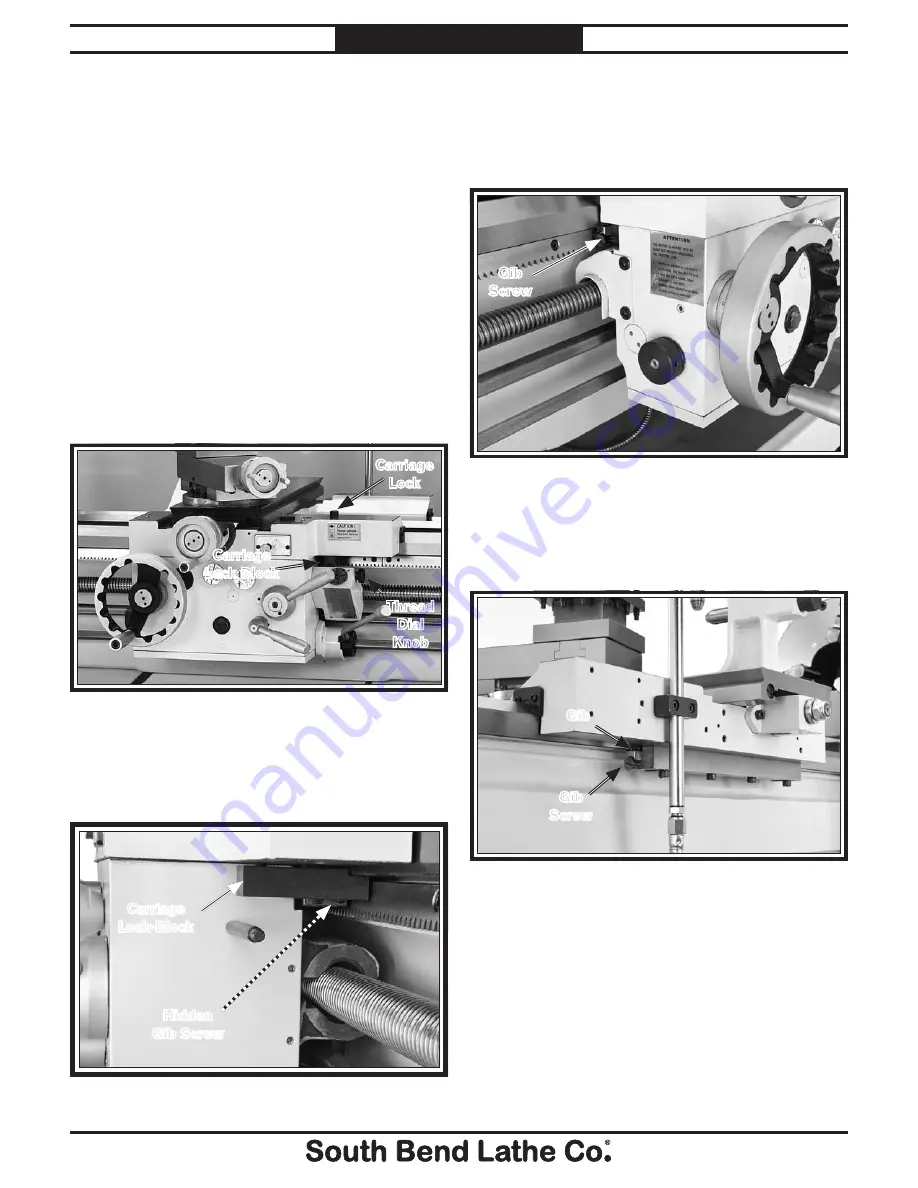

Saddle Gibs

The saddle on this lathe is equipped with

opposing gibs that lie parallel with one another

on either side of the saddle. To tighten the saddle

and remove play, the front gib must move toward

the tailstock, and the rear gib must move toward

the headstock.

Tools Needed:

Qty

Hex Wrench 6mm ................................................. 1

Standard Screwdriver #3 ...................................... 1

To adjust the saddle gibs:

1.

DISCONNECT LATHE FROM POWER!

2.

Remove the thread dial shown in

Figure

137

by removing the lock knob.

Figure 139. Location of carriage lock and half nut for

removal.

Carriage

Lock Block

3.

Remove the carriage lock and the carriage

lock-block shown in

Figures 137–140

.

Carriage

Lock

4.

To tighten the front saddle gib (

Figure 141

)

and move it toward the tailstock, loosen

the tailstock-facing gib screw

1

⁄

4

-turn, and

tighten the headstock-facing gib screw

1

⁄

4

-turn.

Thread

Dial

Knob

Hidden

Gib Screw

Figure 140. Gib screw access.

Figure 141. Front saddle gib screw.

Gib

Screw

5.

To tighten the rear saddle gib (

Figure 142

)

and move it toward the headstock, loosen

the headstock-facing gib screw

1

⁄

4

-turn, and

tighten the tailstock-facing gib screw

1

⁄

4

-turn.

Figure 142. Rear saddle gib and screw.

Gib

Screw

Gib

6.

Test the feel of the carriage by turning the

handwheel. Re-adjust the gib screws in the

same manner to tighten or loosen the gibs.

Most machinists find that the ideal gib

adjustment is one where a small amount

of drag or resistance is present yet the

handwheels are still easy to move.

7.

Reinstall carriage lock and the thread dial.

Carriage

Lock-Block