For Machines Mfg. Since 7/09

EVS Toolroom Lathes

-21-

P R E P A R A T I O N

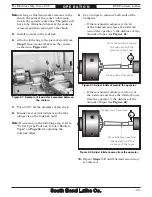

Do not leave the lathe unattended during the

break-in period. Make sure that you keep a

close eye on the headstock oil thermometer

(Figure 29) on the oil reservoir. If the

headstock oil temperature reaches 160°F,

shut the lathe down and let the system cool

before resuming break-in.

Figure 29. Oil temperature thermometer.

4.

Move the feed direction forward/reverse lever

(

Figure 28

) to the neutral position.

Figure 28. Feed direction lever in neutral position.

F

ORWARD

R

EVERSE

N

EUTRAL

Spindle Break-In

It is essential to closely follow the proper break-in

procedures to ensure trouble-free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual and

completed the test run.

To complete the spindle break-in:

1.

Successfully complete the

Test Run

procedure beginning on

Page 17

.

2.

Move the gearbox range lever to low range

position, as shown in

Figure 26

.

Figure 26. Gearbox range lever-break in.

L

OW

N

eutral

H

IGH

3.

Turn the spindle speed dial (

Figure 27

) all

the way counterclockwise to the minimum

speed, and move the spindle speed range

lever to the low range.

Figure 27. Spindle speed controls.

Low

20-400 RPM

High

400-2500 RPM

Spindle Speed Dial

Spindle Speed

Lever