For Machines Mfg. Since 7/09

EVS Toolroom Lathes

-67-

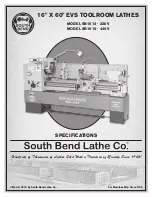

S E R V I C E

Half Nut Adjustment

The half nut mechanism can be tightened if it

becomes loose from wear. The pressure exerted

by the half nut is controlled by a gib similar to

the one in the saddle, which is on

Page 66

. The

half nut gib is adjusted with two set screws.

Tool Needed:

Qty

Hex Wrench 3mm ................................................. 1

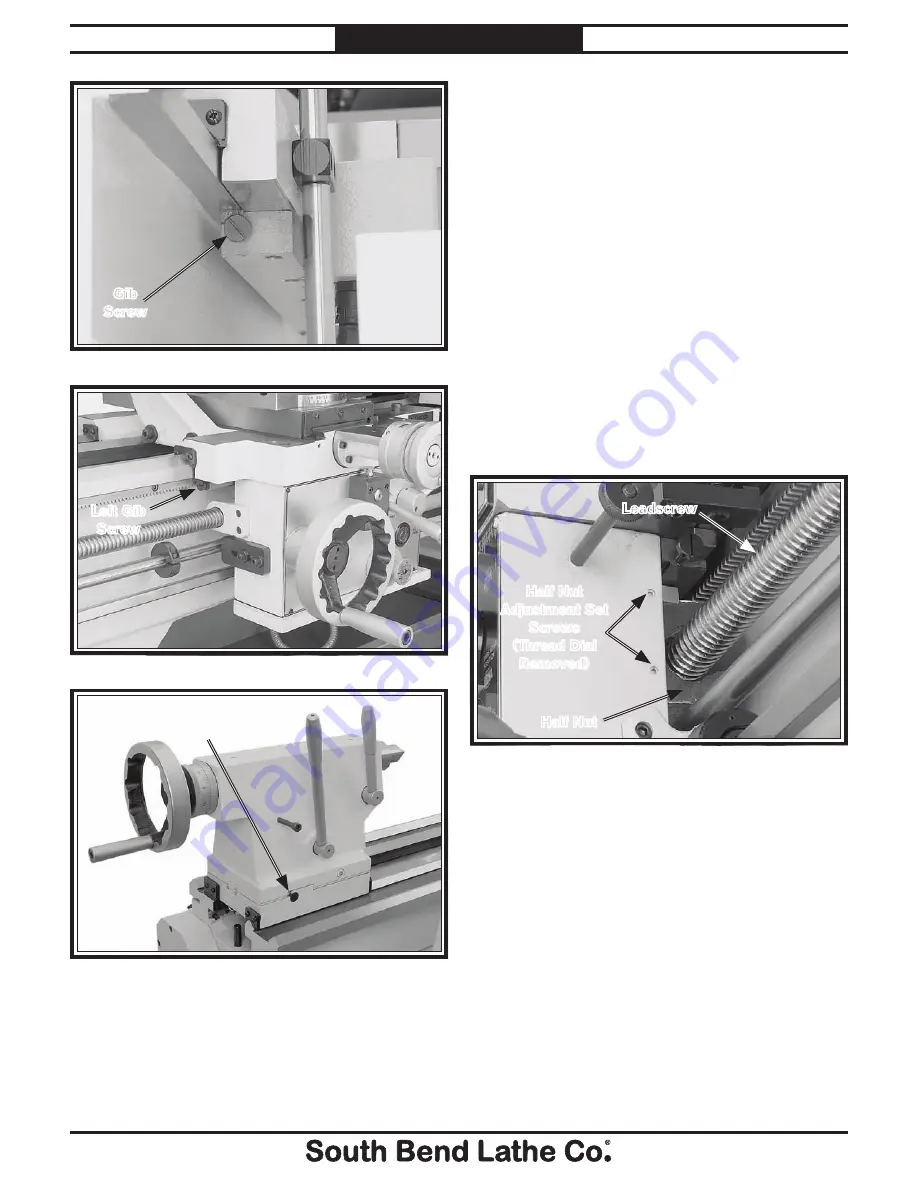

To adjust the half nut:

1.

Disengage the half nut.

2.

Remove the thread dial.

3.

Turn the two half-nut adjustment set screws,

shown in

Figure 132

, clockwise about an

1

⁄

8

th

of a turn.

Figure 132. Half nut gib adjustment.

Leadscrew

Half Nut

Adjustment Set

Screws

(Thread Dial

Removed)

Half Nut

Right Gib Screw

Figure 131. One of two tailstock gib screws.

4.

Engage/disengage the half nut several times

and notice how it feels (you may need to

move the carriage handwheel slightly to get

the half nut to close).

The half nut is correctly adjusted when it

has a slight drag while opening and closing.

The movement should not be too stiff or too

sloppy.

5.

Repeat

Steps 3–4

, if necessary, until you are

satisfied with the half nut adjustment. (If

the half nut becomes too stiff, turn the set

screws counterclockwise to loosen it.

6.

Re-install the thread dial.

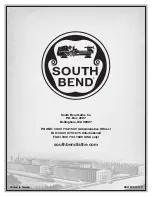

Figure 130. One of two front saddle gib screws.

Left Gib

Screw

Figure 129. One of two rear saddle gib screws.

Gib

Screw