-44-

For Machines Mfd. Since 12/20

South Bend Tools

Model SB1117

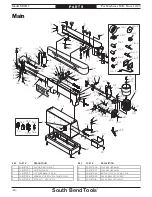

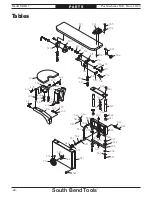

P A R T S

Machine Labels

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

501

PSB1117501

BELT ROTATION LABEL

506

PSB1117506 MODEL NUMBER LABEL

502

PSB1117502

DOOR CLOSED LABEL

507

PSB1117507

ELECTRICITY LABEL

503

PSB1117503

MACHINE ID LABEL

508

PSB1117508 TOUCH-UP PAINT, SB DARK BLUE

504

PSB1117504

MACHINE WARNINGS LABEL

509

PSB1117509 TOUCH-UP PAINT, SB LIGHT BLUE

505

PSB1117505

SOUTH BEND NAMEPLATE 203MM

SB1117

WARNING!

!

INJURY HAZARD

Keep door closed

while machine is

operating.

Disconnect power

before opening

door.

BELT ROTATION

WARNING!

!

EYE/LUNG INJURY

HAZARD

Always wear ANSI-

approved safety

glasses and

respirator when

using this

equipment.

INJURY HAZARD

Do not use machine

if you have not read

the manual. Visit

southbendtools.com

or call 360-734-1540

to get a manual.

WARNING!

!

WARNING!

!

ABRASION INJURY

HAZARD

DO NOT touch

moving sanding belt

or personal injury

may occur!

WARNING!

!

!

INJURY/SHOCK

HAZARD

To avoid shock or

accidental starting,

disconnect power

before adjusting or

servicing machine.

501

502

503

504

505

506

507

508

509

Made in Taiwan to South Bend Specifications

WARNING!

!

Serial No:

MFG Date:

Motor: 3 HP, 220V, 1-Ph, 60 Hz

Full-Load Current Rating: 15A

Sanding Belt Size: 9" x 138-1/2"

Sanding Belt Speed: 4120 FPM

Oscillation Stroke: 1/4"

Main Table Travel: 5-1/8"

End Travel: 8"

Table Tilt: 0 – 45°

Floor-to-Table Height: 33-1/4" – 38-3/8"

Weight: 730 lbs.

MODEL SB1117

9" x 138½" OSCILLATING EDGE SANDER

To reduce the risk of serious injury while using this machine:

1. Read and understand owner’s manual before operating.

2. Always wear approved eye protection and respirator.

3. Only plug power cord into a grounded outlet.

4. Support workpiece with miter gauge, backstop, or worktable.

5. Maintain

1

/

16

" maximum clearance between table and sandpaper.

6. Never touch moving sandpaper.

7. Always sand in accordance with directional arrows on machine.

8. Make sure sander is properly assembled, adjusted, and stable before operating. Only operate

with all guards in place.

9. Never sand pointed stock with point facing into sanding rotation, and never force workpiece

into sanding surface.

10. Only remove jammed pieces when sandpaper is stopped.

11. Turn motor OFF and disconnect power before changing sandpaper, removing jammed pieces,

making adjustments, or servicing.

12. Do not wear loose clothing, gloves, jewelry, or other articles that can get entangled. Tie back

long hair and roll up sleeves.

13. Never reach over moving sanding belt.

14. Do not expose to rain or use in damp locations.

15. Do not operate under influence of drugs or alcohol, or when tired.

16. Prevent unauthorized use by children or untrained users; restrict access or disable machine

when unattended.

SINCE

1906

The safety labels provided with your machine are used to make the operator aware of the

machine hazards and ways to prevent injury. The owner of this machine MUST maintain the

original location and readability of these safety labels. If any label is removed or becomes

unreadable, REPLACE that label before using the machine again. Contact South Bend Tools at

(360) 734-1540 or www.southbendtools.com to order new labels.

SB1117 Machine Labels (A)

(3/1/21)

• 1:1 Scale (Labels are

actual size)

• Labels must be made of

chemical-resistant material

COLOR CODES

SOUTH BEND LOGO RED

PANTONE 180 C or RAL 2002

PANTONE 151 C or RAL 2003

WARNING

CAUTION

PANTONE 109 C

DANGER

PANTONE 485 C or RAL 3001

SOUTH BEND YELLOW

PANTONE 122 C or RAL 1032

WARNING!

!

INJURY HAZARD

Keep door closed

while machine is

operating.

Disconnect power

before opening

door.

COPYRIGHT © SOUTH BEND TOOLS

FOR SOUTH BEND MACHINES ONLY!

DO NOT REPRODUCE OR CHANGE THIS ARTWORK WITHOUT

WRITTEN APPROVAL! South Bend will not accept labels changed without approval.

If artwork changes are

required, contact us immediately at manuals@southbendtools.com.

Made in Taiwan to South Bend Specifications

WARNING!

!

Serial No:

MFG Date:

Motor: 3 HP, 220V, 1-Ph, 60 Hz

Full-Load Current Rating: 15A

Sanding Belt Size: 9" x 138-1/2"

Sanding Belt Speed: 4120 FPM

Oscillation Stroke: 1/4"

Main Table Travel: 5-1/8"

End Travel: 8"

Table Tilt: 0 – 45°

Floor-to-Table Height: 33-1/4" – 38-3/8"

Weight: 730 lbs.

MODEL SB1117

9" x 138½" OSCILLATING EDGE SANDER

To reduce the risk of serious injury while using this machine:

1. Read and understand owner’s manual before operating.

2. Always wear approved eye protection and respirator.

3. Only plug power cord into a grounded outlet.

4. Support workpiece with miter gauge, backstop, or worktable.

5. Maintain

1

/

16

" maximum clearance between table and sandpaper.

6. Never touch moving sandpaper.

7. Always sand in accordance with directional arrows on machine.

8. Make sure sander is properly assembled, adjusted, and stable before operating. Only operate

with all guards in place.

9. Never sand pointed stock with point facing into sanding rotation, and never force workpiece

into sanding surface.

10. Only remove jammed pieces when sandpaper is stopped.

11. Turn motor OFF and disconnect power before changing sandpaper, removing jammed pieces,

making adjustments, or servicing.

12. Do not wear loose clothing, gloves, jewelry, or other articles that can get entangled. Tie back

long hair and roll up sleeves.

13. Never reach over moving sanding belt.

14. Do not expose to rain or use in damp locations.

15. Do not operate under influence of drugs or alcohol, or when tired.

16. Prevent unauthorized use by children or untrained users; restrict access or disable machine

when unattended.

SINCE

1906

BELT ROTATION