24.

Re-tighten both dovetail cap screws to secure

the zero setting.

25.

Move the carriage toward the tailstock until

the taper attachment body is against the

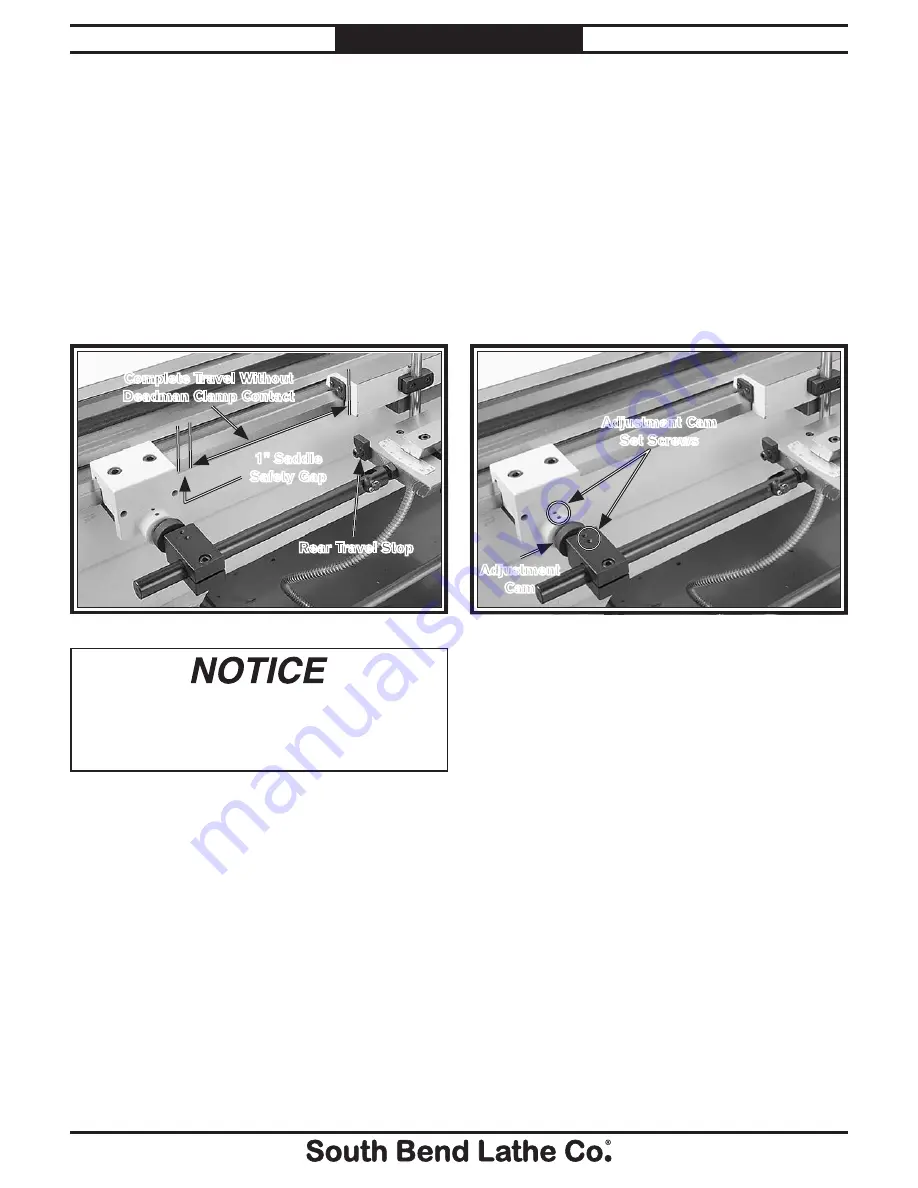

rear travel stop (see Figure 18).

Note:

If necessary, reposition the deadman clamp

on the arm so that it is at least 1" away from

the saddle (see Figure 18) and re-tighten

the clamp cap screws. This “saddle safety

gap” will prevent the saddle crashing into

the deadman clamp during taper operations.

27.

Inspect the assembly to determine if the

deadman arm is parallel horizontally and

vertically with the bedway.

— If the arm is parallel horizontally and

vertically with the bedway, proceed to

Step 26.

— If the arm is not horizontally parallel with

the bedway:

a.

Loosen the four adjustment cam set

screws shown in

Figure 19.

Figure 18. Saddle gap.

Complete Travel Without

Deadman Clamp Contact

1" Saddle

Safety Gap

Rear Travel Stop

b.

Slide the adjustment cam and arm

clamp toward or away from the

deadman clamp until the arm is

horizontally parallel with the bedway.

c.

Re-tighten the adjustment cam set

screws.

— If the arm is not vertically parallel with

the bedway:

a.

Loosen the four adjustment cam set

screws shown in Figure 19.

b.

Rotate the knurled adjustment cam

until the arm is vertically parallel with

the bedway.

c.

Re-tighten the adjustment cam set

screws.

You will need to perform Step 25 each time

you secure the deadman clamp to the bedway

to cut a taper to prevent the carriage crashing

into the deadman clamp.

26.

Move the carriage toward the headstock

until the taper attachment is against the

front travel stop.

Note:

In the following step, it may be necessary

to rotate the arm so the clevis allows the arm

to tilt in a particular direction.

Figure 19. Adjustment cam set screws.

Adjustment

Cam

Adjustment Cam

Set Screws

-8-

Mfg. Since 9/11

Model SB1263

I N S T R U C T I O N S

Summary of Contents for SB1263

Page 16: ......