-82-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

S E R V I C E

DO NOT rotate the spindle

or input pulley while any

body part is inside the

headstock. Doing so may

cause entanglement and

serious crushing injuries.

6.

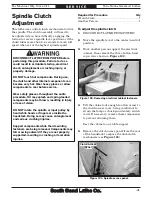

Study Figure 124 to determine the

adjustments that will be required in the

following steps.

Symptom

Required Action

Spindle lever will not

engage FORWARD.

Loosen Forward

Adjustment Ring as

needed.

Spindle lever will not

engage REVERSE.

Loosen Reverse

Adjustment Ring as

needed.

Chuck takes more

than 3–4 seconds to

reach full speed in

FORWARD.

Tighten Forward

Adjustment Ring one

notch.

Chuck takes more

than 3–4 seconds to

reach full speed in

REVERSE.

Tighten Reverse

Adjustment Ring one

notch.

Figure 124. Clutch adjustment overview.

Loosen

Loosen

Tighten

Tighten

Reverse Drive

Clutch

Forward Drive

Clutch

Forward Adjustment

Ring

Reverse Adjustment

Ring

Clutch components get hot

during operation. To avoid

burn injuries, wear heavy

leather gloves or allow

components to cool before

service.

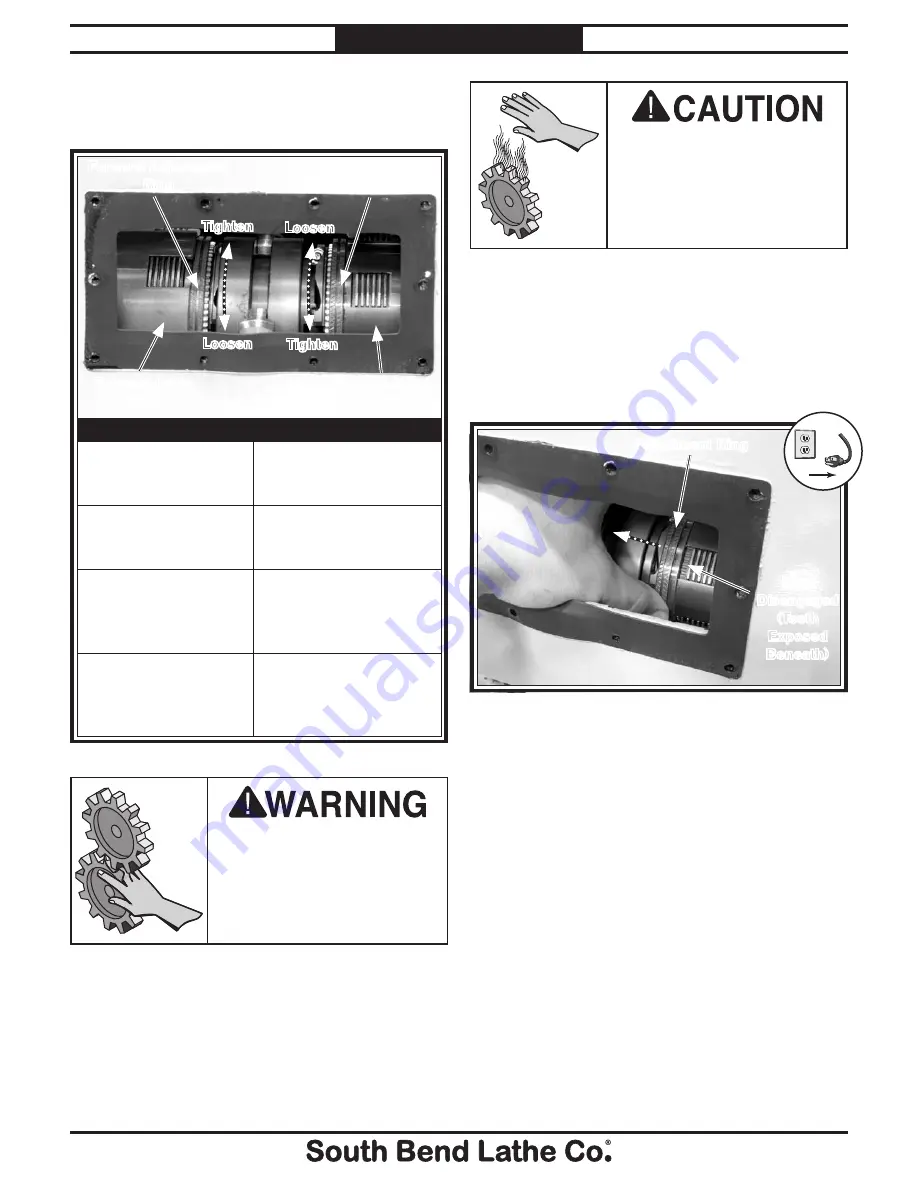

7.

Use a metal scribe or permanent marker

to mark the position of the adjustment

ring relative to its clutch assembly, then

use a small screwdriver to pry and slide

the necessary adjustment ring away from

its corresponding clutch to unlock it (see

Figure 125).

Figure 125. Disengaging adjustment ring

(reverse side shown).

Adjustment Ring

Ring

Disengaged

(Teeth

Exposed

Beneath)

!

If you have difficulty disengaging the ring,

make sure the spindle lever is in the middle

(neutral) position. When the ring is fully

disengaged, it will spin freely.

— If you are loosening the adjustment ring,

continue to Step 8.

— If you are tightening the adjustment ring,

skip to Step 9.

Summary of Contents for TURN-NADO SB10146PF

Page 138: ......