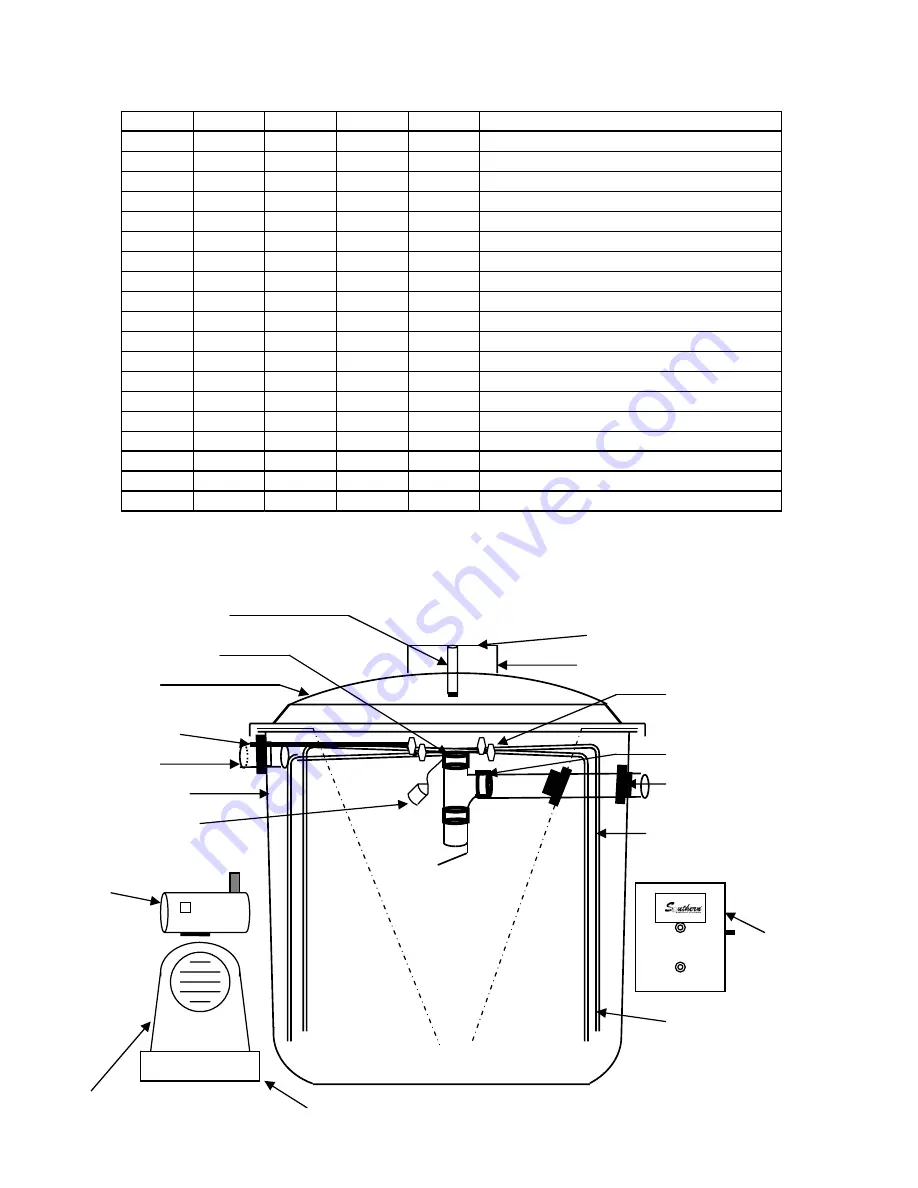

15.Comp. Cover

17. Control Panel

PART NO. PART NO. PART NO. PART NO. PART NO. DIAGRAM NUMBER DESCRIPTION

SM-501

SM-601

SM-701

SM-1001

SM-1501 1. FIBERGLASS AERATION TANK

SM-502

SM-602

SM-702

SM-1002

SM-1502 2. P.E. or F.G. CLARIFIER CONE

SM-503

SM-603

SM-703

SM-1003

SM-1503 3. FIBERGLASS DOME LID

SM-504

SM-604

SM-704

SM-1004

SM-1504 4. P. E. RISER 24"X6"

SM-505

SM-605

SM-705

SM-1005

SM-1505 5. P. E. RISER LID 24"

SM-506

SM-606

SM-706

SM-1006

SM-1506 6. PVC Union (TYP. 4)

SM-507

SM-607

SM-707

SM-1007

SM-1507 7. PVC AIR INLET LINE

SM-508

SM-608

SM-708

SM-1008

SM-1508 8. PVC FOUR WAY CROSS

SM-509

SM-609

SM-709

SM-1009

SM-1509 9. PVC AIR DROP LINE (TYP. 4)

SM-510

SM-610

SM-710

SM-1010

SM-1510 10. PVC AIR DIFFUSER (TYP. 4) Optional

SM-511

SM-611

SM-711

SM-1011

SM-1511 11. 4" SCH 40 PVC INLET

SM-512

SM-612

SM-712

SM-1012

SM-1512 12. 4" SCH 40 PVC OUTLET ASSEMBLY

SM-513

SM-613

SM-713

SM-1013

SM-1513 13. NEOPRENE SEAL (TYP. 3)

SM-514

SM-614

SM-714

SM-1014

SM-1514 14. AIR COMPRESSOR

SM-515

SM-615

SM-715

SM-1015

SM-1515 15. COMPRESSOR COVER

SM-516

SM-616

SM-716

SM-1016

SM-1516 16. COMPRESSOR BASE

SM-517

SM-617

SM-717

SM-1017

SM-1517 17. CONTROL PANEL

SM-518

SM-618

SM-718

SM-1018

SM-1518 18. SENSOR FLOAT

SM-519

SM-619

SM-719

SM-1019

SM-1519 19. SAMPLE STACK

16. Comp. Base

2. Clarifier Cone

14. Air Compressor

SM500 SM600 SM750 SM1000 SM1500

MODEL NO.’S

PARTS LIST & DIAGRAM

1. Aeration Tank

3. Lid Dome

7. Air Inlet Line

9. PVC Air Drop Line (TYP. 4)

10. Air Diffuser (TYP. 4)

OPTIONAL

11. PVC Inlet

12. PVC Outlet Pipe & Tee’s

13. Neoprene Seal (TYP. 3)

4. PE Riser 24”Dia. x 6”H

5. PE Riser Lid 24” Dia.

6. PVC Union (TYP. 4)

8. Four way Cross

19. Sample Stack

Note: Sensor float is located in pump tank on all spray irrigation disposal systems

HIGH WATER

ALARM

AIR COMPRESSOR

FAILURE

18. High Water Alarm

Sensor Float

Rev. By RC 07/30/01

9