Before Starting Engine:

A

Adding Fuel to Cultivator:

B

1. Stop engine and allow it to cool before refueling.

2. Place the unit upright on the ground or on a sturdy bench and wipe and any debris from around the fuel cap.

3. Remove fuel cap slowly and use a funnel to pour the mixture into the tank, and replace the fuel cap.

4. Avoid spilling fuel or oil. Wipe up all fuel spills.

5. Move at least 10 feet (3 meters) away from fueling site before starting engine.

Operation

• Save all instructions

Questions? Call Toll Free at 1-800-737-2112

7

Copyright © 2009 MAT Engine Technologies, LLC

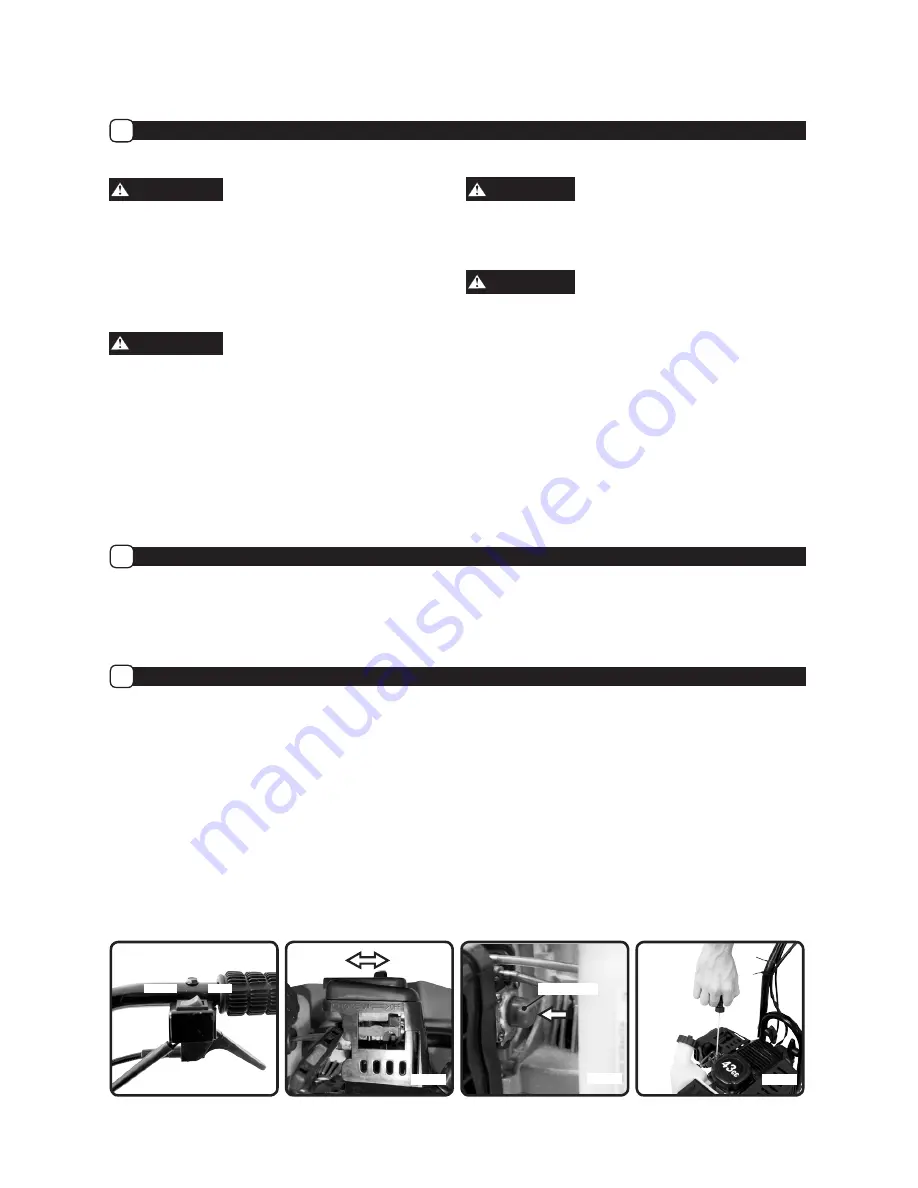

Fig. 6

Fig. 9

Fig. 7

COLD START

RUN/WARM

START

Fig. 8

PRIMER BULB

Mixing Fuel / 2-Cycle Oil

WARNING

Do not smoke or allow smoking near fuel or the cultivator.

Mix and pour fuel outdoors WHERE THERE ARE NO

SPARKS OR FLAMES.

The 2-cycle engine on your cultivator requires that fuel and

2-cycle engine oil need to be pre-mixed before adding to

the fuel tank.

WARNING

Always mix the gasoline and 2-cycle oil in a container

approved for gasoline. Never mix fuel directly in the engine

fuel tank.

Use fresh unleaded gasoline with an octane rating of 87 or

higher and less than 10% ethanol or methanol.

Use 2-cycle oil that meets or exceeds JASO – FC

specifications and is intended for mixing at a fuel to oil

ratio of 40:1.

CAUTION

Use of incorrect gasoline such as diesel fuel or gasoline

containing more than 10% ethanol or methanol will damage

the cultivator engine and void your warranty.

CAUTION

Use of incorrect oil, such as automotive oil, 2-cycle marine

outboard oil, or any oil other than specified oil will damage

the cultivator engine and void your warranty.

To mix the fuel and 2-cycle oil, follow instructions on 2-cycle

oil container for mixing fuel. Mix gasoline and 2-cycle oil

at a ratio of 40:1. A mixture with a 40:1 ratio is obtained

by mixing 1 gallon (4 liters) of gasoline with 3.2 ounces of

oil (95 ml). After adding oil to gasoline, shake container

momentarily to ensure proper mixing.

IMPORTANT: Mix only enough fuel for your immediate

needs. Do not store pre-mixed fuel.

Starting Engine:

C

Starting a Cold Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘cold start’ position. (See

Figure 7)

4. Press the primer bulb slowly 6 times. (See Figure 8)

5. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

6. Pull the recoil starter handle sharply until the engine

starts and runs

7. After engine starts and runs for 10-15 seconds, move

choke lever to “run/ warm start” position. (See Figure 7)

Starting a Warm Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘run/ warm start’ position.

(See Figure 7)

4. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

5. Pull the recoil starter handle sharply until the engine

starts and runs.

ON/RUN

STOP