Summary of Contents for Graphic Whizard PT320 CC

Page 25: ...17...

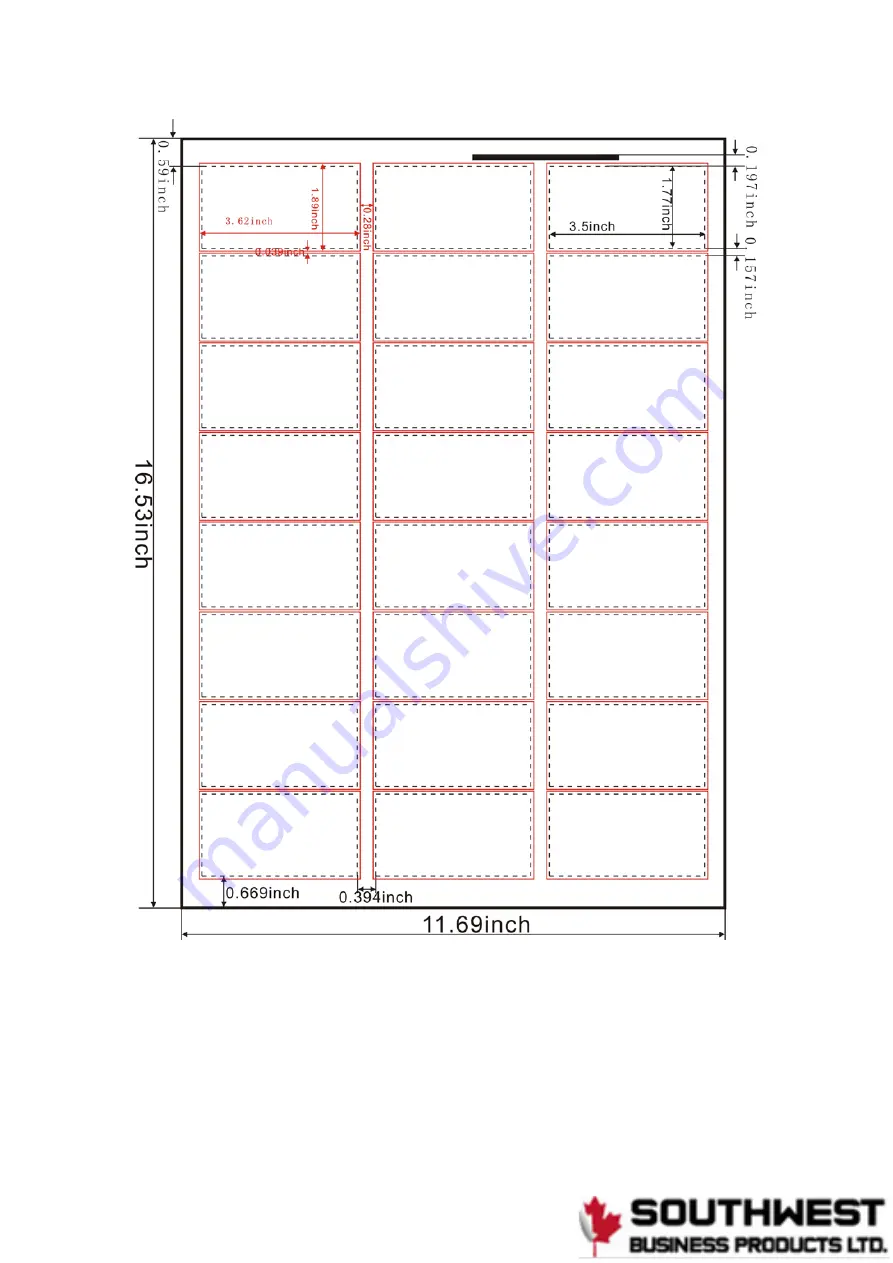

Page 26: ...A3 420 297 88 9mm 45mm 18...

Page 27: ...A3 420 297 88 9mm 50mm 19...

Page 28: ...A3 420 297 88 9mm 54mm 20...

Page 29: ...A3 420 297 88 9mm 50 8mm 21...

Page 30: ...A3 420 297 88 9mm 95mm 22...

Page 31: ...A3 420 297 88 9mm 127mm 23...

Page 32: ...24...

Page 33: ...25...

Page 34: ...26...

Page 35: ...27...

Page 36: ...28...

Page 37: ...88 9mm 40 250 mm customize 29...