Southworth Products

DDL Dock Lift Manual

DDL Dock Lift Manual

17

6.2 Periodic Maintenance

Before each use ensure area is clear of debris and sump/drain is clear. Inspect the machine

for excessive wear or damage and ensure all precautionary labeling is legible. Inspect railings,

verify cables/chains are in place and in good condition. Verify push button switch and cord are

functioning and are not damaged.

6.2.1. Weekly Maintenance

• Inspect leg rollers, center pivot pins and bushings, and leg hinge pins and bushings for

excessive wear or damage. Repair or replace as necessary.

• Inspect machine for loose of broken fasteners. Repair or replace as necessary.

• Inspect labeling. If any label is damaged or otherwise illegible contact the manufacturer

for replacement labels.

6.2.2. Monthly Maintenance

• Perform Weekly Maintenance.

• Apply a light oil or PTFE lubricant to non-greased pivot points or rollers.

•

Inspect the appearance of the hydraulic fluid. The fluid should be transparent and clear

of debris.

•

Inspect all hydraulic hoses and fittings. Repair or replace as necessary.

• Inspect all electrical wiring and connections. Repair or replace as necessary.

• Inspect limit switches, if applicable. Repair, replace, or adjust as necessary.

6.2.3. Six Months

• Perform Monthly and Weekly maintenance.

•

Inspect the hydraulic cylinder and return line. If excessive fluid exists in the vent line,

the cylinder may need to be repacked or replaced.

•

Change hydraulic fluid. Clean the suction screen and vent cap. Replace pressure line or

return line filter element (if equipped).

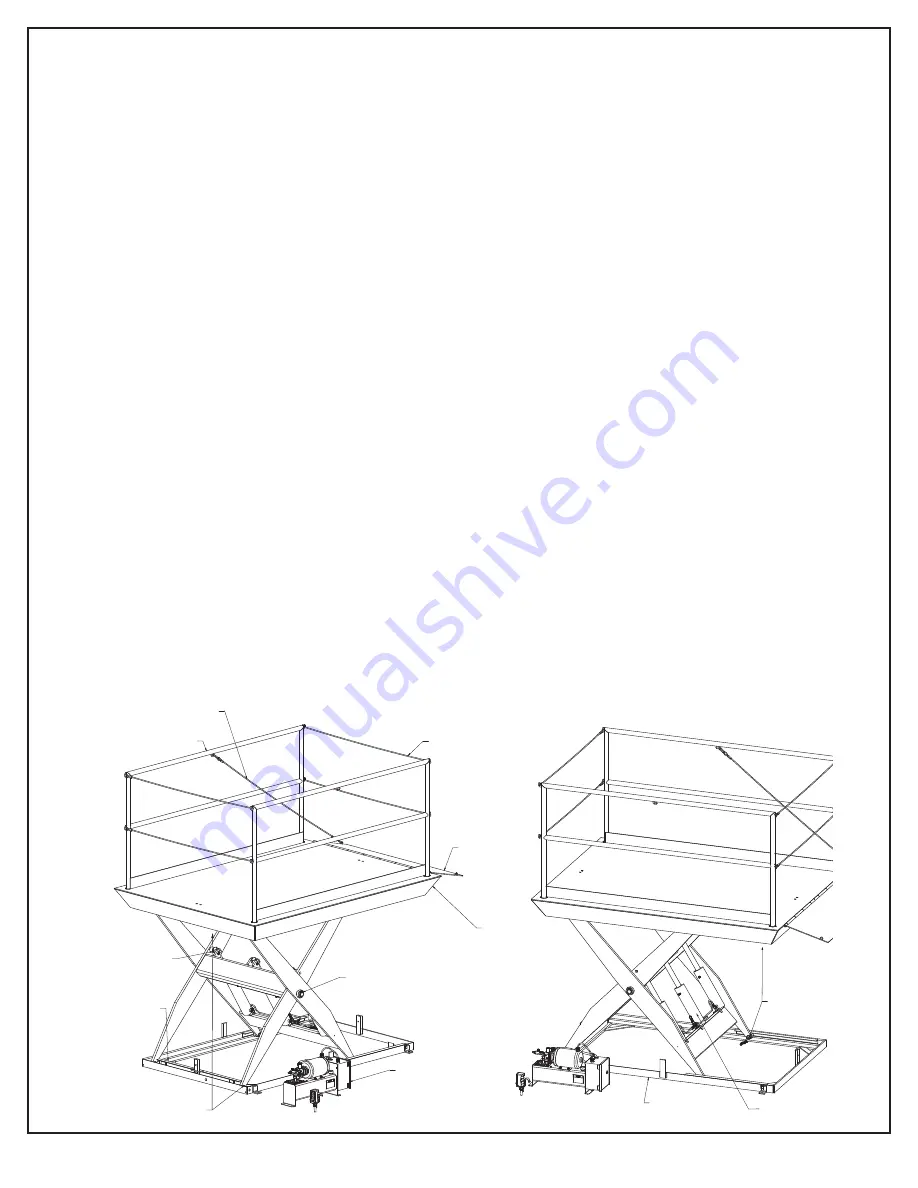

BASE FRAME

RAILINGS (BOTH SIDES)

HYDRAULIC POWER UNIT

(STOWED)

MAINTENANCE

PLATFORM)

PULL CABLE

PLATFORM

SNAP CABLES

(BOTH ENDS OF

DEVICE

HYDRAULIC

CYLINDER PINS

(EACH CYLINDER)

THROW OVER

PLATE

CENTER PIVOT

PINS/BUSHINGS

(BOTH SIDES)

UPPER/LOWER LEG HINGE

PINS/BUSHINGS (BOTH SIDES)

UPPER/LOWER

ROLLERS

(BOTH SIDES)

HYDRAULIC

CYLINDERS