Southworth Products

DDL Dock Lift Manual

DDL Dock Lift Manual

19

6.4 Replacement Parts

Southworth Products has carefully chosen the components in your lift to be the best available

for the purpose. Replacement parts should be identical to the original equipment. Southworth

Products will not be responsible for equipment failures resulting from the use of incorrect

replacement parts or from unauthorized modifications of the machine.

Southworth Products will gladly supply you with replacement parts for your Southworth Products

lift. With your order, please include the model number and the serial number of the lift. You

can find these numbers on the name plate, which is located on the crossbar at the base of the

cylinder(s). When you are ordering parts for a cylinder, also include the cylinder number. This is

stamped on the base of the cylinder housing.

To order replacement parts, please call the Parts Department. See Warranty & Contact

Information section. Parts are shipped subject to the following terms:

• FOB factory

• Returns only with the approval of our parts department.

• Payment net 30 days (except parts covered by warranty).

• Freight collect (except parts covered by warranty).

• The warranty for repair parts is 30 days from date of shipment.

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we ship

the replacement part, then credit you when you return the worn or damaged part, and we verify

that it is covered by our warranty. Labor is not covered under warranty for Parts orders.

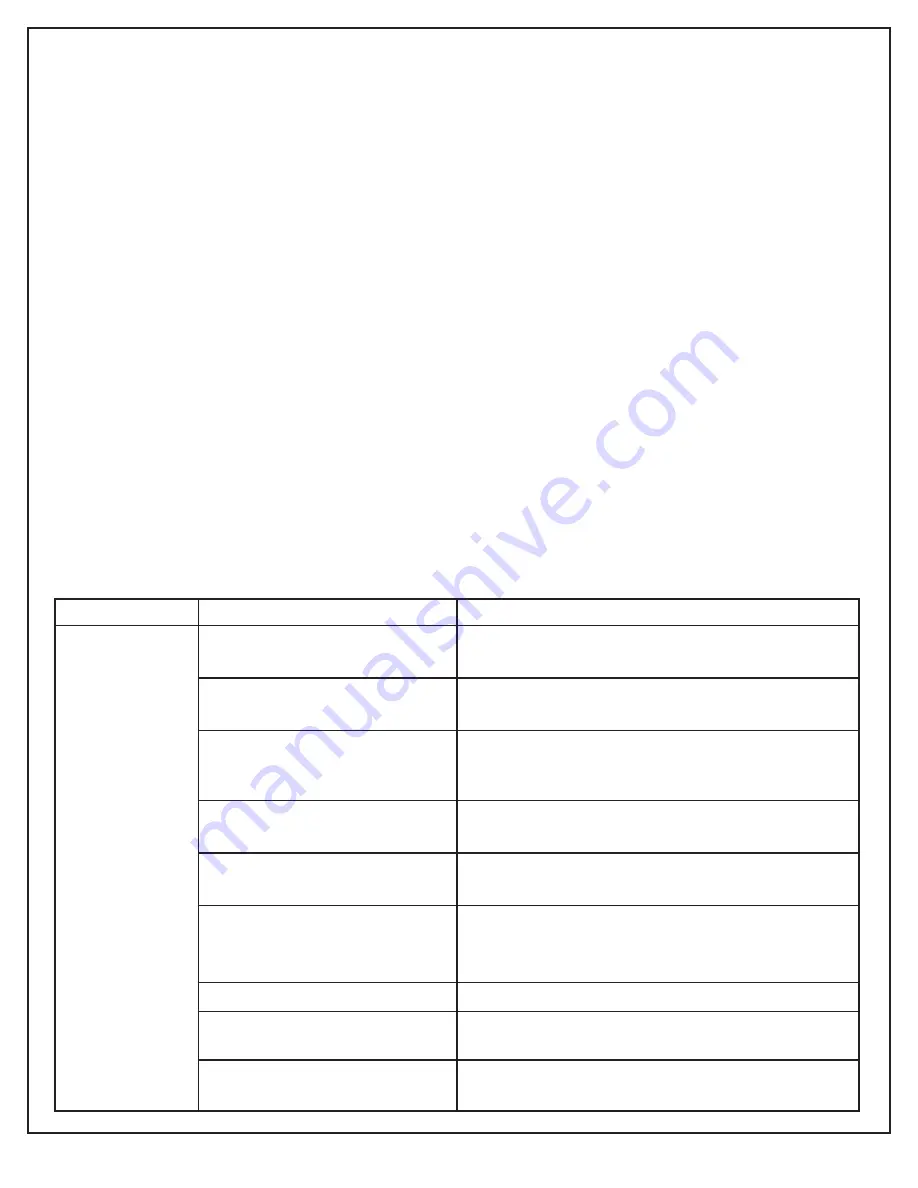

7. Troubleshooting

PROBLEM

POSSIBLE CAUSE

CHECK

Lift will not raise

Load too heavy

Make sure the load does not exceed the rated

capacity.

Power unit not receiving

power.

Verify that the power unit is receiving power.

See

Electrical Information Section.

Hand controls may be

malfunctioning or may not be

receiving power.

Verify that the controls are receiving power

and are functioning correctly.

See Electrical

Information Section.

Motor contactor may be

malfunctioning.

Verify motor contactor is functioning.

See

Electrical Information Section.

Motor may be turning in wrong

direction.

Swap any two phases of the motor power leads.

Hydraulic Fluid low

With lift in fully lowered position the fluid level

should be approximately 3/4” from the top of the

tank.

Lift has reached it upper limit. Upper limit switch may need to be adjusted

Motor voltage too low

Supply voltage must be ± 10% of the rated

voltage at the motor terminals.

Tank vent plugged

Make sure vent plug on hydraulic tank is

installed and not blocked.