Southworth Products

PUN Manual

22

standard lock-out/tag-out procedures.

4. Disconnect the hydraulic supply line to the bottom end of the cylinder. Place the

free end into a container to collect the used oil.

5. Repeat the same procedure for the hydraulic supply line to the top end of the

cylinder.

6. At the top end of the rod remove the “keeper” from the upper cylinder clevis and

drive out the upper clevis pin. Repeat the same procedure to remove the lower

cylinder clevis pin.

7.

Push the rod back into the cylinder to drive the hydraulic fluid out through the

hose and into the container. You may use air pressure at the hydraulic port to do

this.

8. Now the cylinder can be removed for repacking

or replacement.

8.7 Repacking a Cylinder

Repacking the cylinders requires special training

and tools. If you are not familiar with repacking

procedures, this work should be left to a qualified

hydraulic repair shop.

During reassembly, it is very important to keep all

of the parts free of dirt, dust, metal chips, water,

and other contamination. Most of the problems with

hydraulic systems are caused by contamination in

the oil.

1. Begin by removing the cylinder as described in the

last section.

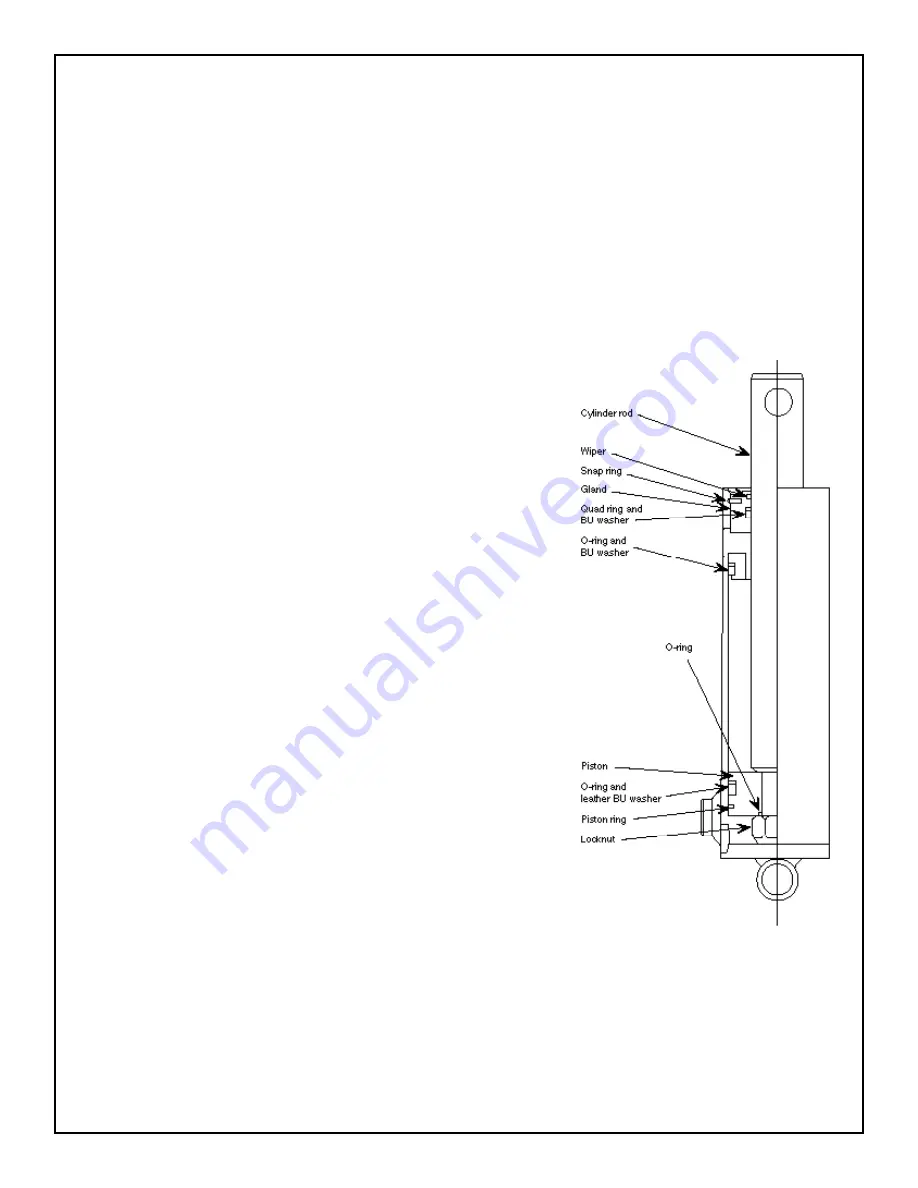

2. The image shows the parts inside a cylinder. Secure

the cylinder in a vise so that it cannot turn. Clear the

work area so that you can lay the parts on a clean

surface.

3. At the upper end of the cylinder, remove the snap

ring. Pull the rod to within 3 inches of full extension.

Compress the ring and, at the same time, pull

outward on the rod. This will pull the gland out of the

cylinder.

4.

Pull the rod and piston all of the way out of the cylinder. This assembly is heavy! Be

careful not to drop it as it comes free.

5. Remove the piston from the cylinder rod. (Be careful to protect the cylinder rod as you

do this. Any burrs on the rod could damage the packing.) Note the position of the piston

ring and remove it. Remove the leather BU washer and larger O-ring from the piston.