6

Southworth Products

FPS3000-43NAS Manual

4. Electrical cables and wiring harness

5. Loose or missing parts

6. Nameplates, precautionary and instructional markings and/or labeling

7. Guarding system

8. Items specified by the manufacturer

Problem or Malfunctions

- Any problems or malfunctions that affect the safety of operations shall

be repaired prior to the use of the machine.

Before Operations -

The operator shall:

1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules or

have them explained

2. Understand all labels, warnings, and instructions displayed on the machine or have them

explained.

Workplace Inspections

- Before the machine is used and during use, the operator shall check

the area in which the machine is to be used for possible hazards such as, but not limited to:

1. Bumps, floor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions

- The operator shall ensure the operation of the machine

is in compliance with the following:

1.

Guarding system

- Guarding shall be installed and positioned, and access gates or

openings shall be secured per the manufacturer’s instructions (If applicable).

2.

Distribution of load

- The load and its distribution on the platform shall be in accordance

with the manufacturer’s rated capacity for that specific configuration.

3.

Maintaining overhead clearance

- The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

4.

Point of Operation

- The operator shall not place any part of their body under the platform.

5.

Precaution for moving equipment

- When other moving equipment or vehicles are

present, special precautions shall be taken to comply with the safety standards established

for the workplace.

6.

Reporting problems or malfunctions

- The operator shall immediately report to a

supervisor any problem(s) or malfunction(s) that become evident during operation. The

operator shall ensure all problems and malfunctions that affect the safety of operations are

repaired prior to continued use.

7.

Capacity limitation

- Rated capacity shall not be exceeded when loads are transferred to

the load enclosure.

8.

Work area

- The operator shall ensure the area surrounding the machine is clear of

personnel and equipment before lowering the load enclosure.

9.

Securing the machine

- The operator shall comply with the means and procedures

provided to protect against use by an unauthorized person(s).

Summary of Contents for Stack-N-Go FPS3000-43NAS

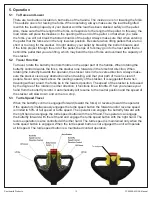

Page 20: ...20 Southworth Products FPS3000 43NAS Manual 9 Control Pod 9 1 August 2018 and Prior...

Page 21: ...21 Southworth Products FPS3000 43NAS Manual 9 2 September 2018 to Present...

Page 22: ...22 Southworth Products FPS3000 43NAS Manual 10 Steering Assembly 10 1 August 2018 and Prior...

Page 23: ...23 Southworth Products FPS3000 43NAS Manual 10 2 September 2018 to Present...

Page 29: ...29 Southworth Products FPS3000 43NAS Manual 16 Hydraulic Schematic...

Page 32: ...32 Southworth Products FPS3000 43NAS Manual...

Page 33: ...33 Southworth Products FPS3000 43NAS Manual 18 2 November 2017 to Present...