30

31

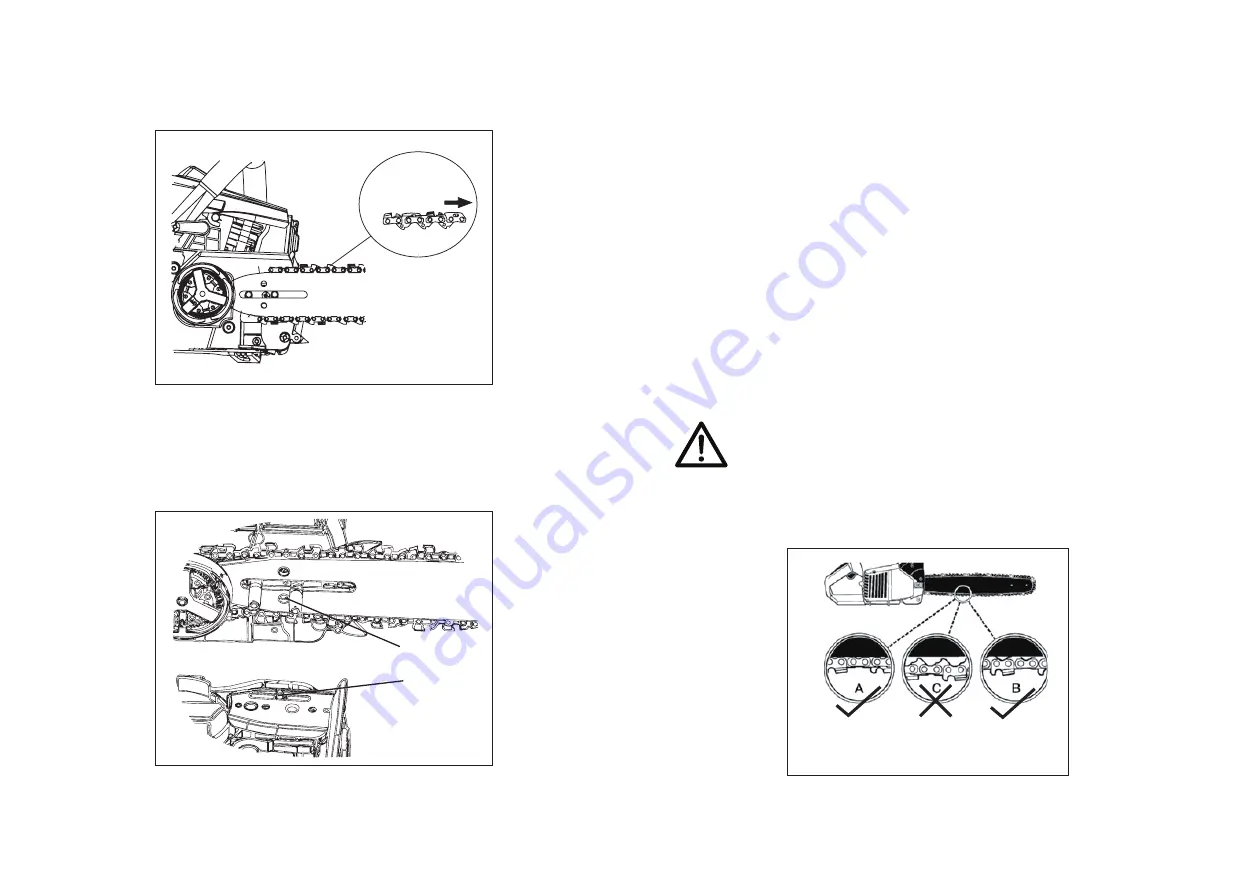

3. Fit the chain around the bar ensuring that the direction of the

chain is as depicted in the picture on the bar. Fit the chain on

the sprocket. Adjust the position of chain tensioner so the

tensioner pin locates in the hole (A) on the bar.

Direction of chain

4. Adjust the tension to ensure that there is not too much slack

in the chain. Make sure the tensioner pin (B) is located in the

assembly hole (A) on the bar. Pay attention to the correct

direction of the saw chain. Compare with the picture near the

chain sprocket and the picture on the bar.

A

B

5. Fit the chain cover to the power unit and fasten the nuts to

the chainsaw, ensure these are fastened as tight as possible

using your fingers only.

6. While holding up the tip of the bar, adjust the chain tension

by turning the adjustment wheel until the chain engages

in the bar channel. When tensioned correctly, it should be

possible to pull one full chain link free of the bar channel with

ease.

7. Tighten the wheel as secure as you can using your fingers.

Then check the chain for smooth rotation and proper tension

while moving it by hand. If necessary, loosen the chain cover.

8. Tighten the tensioner wheel.

NOTE

: A new chain will expand its length during the first period

of use. Check and re-adjust the tension frequently, as a loose

chain can easily derail or cause rapid wear of itself and the chain

bar.

CAUTION!

If the saw chain is TOO LOOSE or TOO TIGHT

the V-drive wheel, chain bar, chain and crank shaft bear-

ing will suffer premature wear. Below Fig. shows the cor-

rect tension A (when cold) and tension B (when warm).

Fig. C shows a chain that is too loose.