Form 44201360

22

Oct 2019

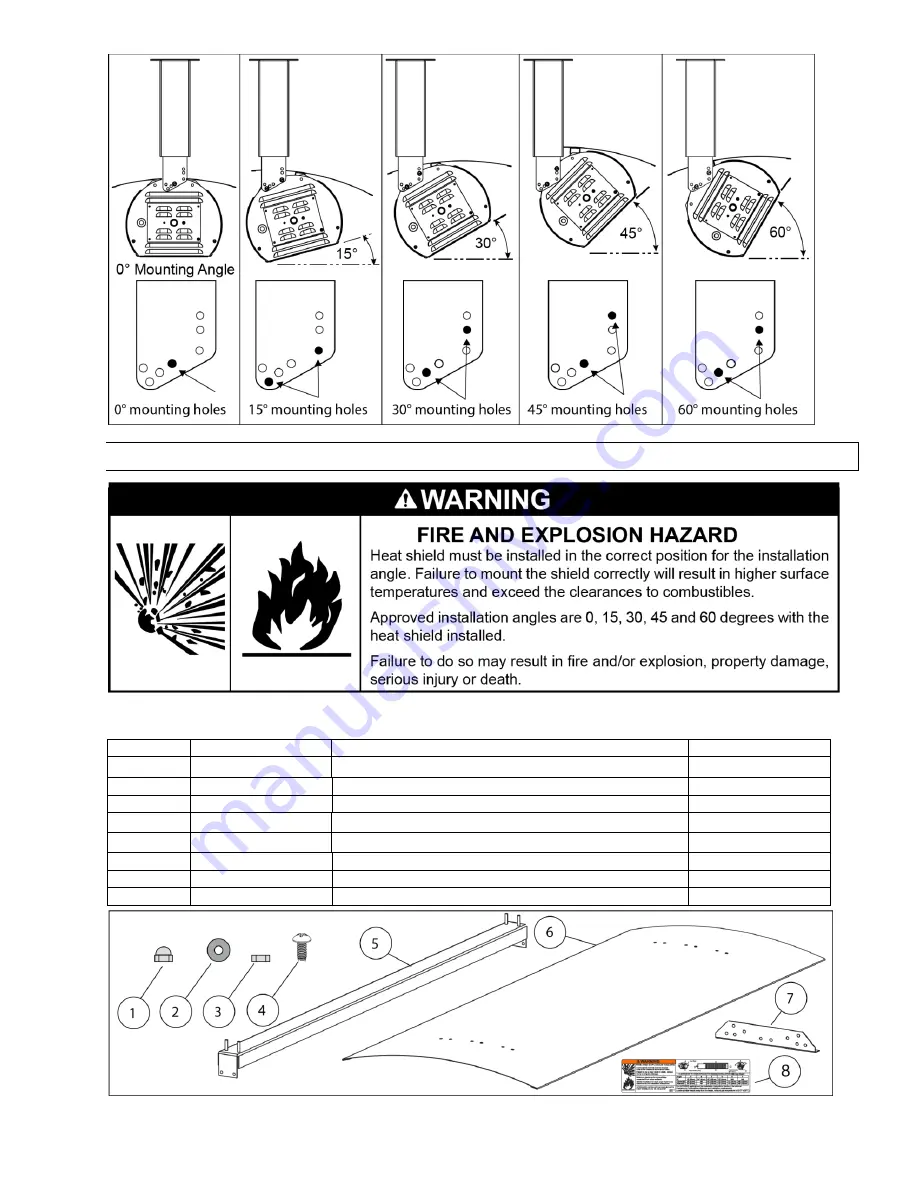

HEAT SHIELD INSTALLATION

13.0)

A heat shield can be used to reduce the clearance to combustible distances. Refer to Minimum Clearance to

Combustibles in Section 4). The heat shield is available as an accessory Kit No. 44566300.

Item No.

Part No.

Description

Quantity

1

02359000

#10-24 DOME CAP NUT

2

2

02358000

TEFLON WASHER

4

3

02186010

#10-24 SS LOCKNUT NUT

2

4

02352000

PHSMS #8 x 1/2" AB POINT SS - BLK OXIDE

8

5

44568139

RAIL - HEAT SHIELD HANGER - PAINTED

1

6

44566189

HEAT SHIELD - ROLLED/PAINTED

1

7

44568149

HOLDER BRACKET - PAINTED

2

8

43247112

LABEL, INDOOR CLEARANCES (with heat shield)

1