–9– Form

#43219000

Jan 09

11) CLEANING AND ANNUAL MAINTENANCE

This heater must be cleaned and serviced at least once before the start of each heating season or at any time the infrared

emitter shows signs of collecting any foreign material on its surface or in the ports, or when anything obstructs the venturi or

the screen. Maximum heating efficiency and clean combustion will be maintained by keeping the emitter and burner clean.

To clean the heater, follow these instructions:

1) Turn off all gas supply to the heater.

2) Clean the reflector.

3) Remove he main burner orifice and the pilot orifice (if so equipped) and clean them thoroughly.

4) Check the venturi opening to be sure it is clean. If there is any evidence of dirt accumulation in the venturi, remove it

before cleaning to avoid getting the dirt inside the heater.

5) Inspect the emitter surface to be sure it is clean. Ignite the heater and observe the color of the emitter face. If there are

pronounced dark areas on the face, it probably indicated an accumulation of dirt on the inside surface and the following

steps must be taken to clean that surface:

a) Lower the heater to the floor or other suitable working surface.

b) Remove the reflector from the reflector mounting panels or collar.

c) Disconnect the electrode cable and flame sensor cable, or pilot burner tubing.

d) Remove the reflector mounting panels from the heater body

e) Remove the emitter face from the heater body. This surface unit is attached by ¼” Hex Head machine screws (10

on the RSCA3, 16 on the RSCA6, and 26 on the RSCA10)

Use caution in this operation as the emitter surface

is fragile.

f)

Carefully brush any foreign material from the back side of the emitter face and the inside of the heater.

g) The insulation gasket which was between the heater body and the emitter face must be replaced when the heater is

reassembled. Order two (2) of each of the part numbers indicated for your particular model:

RSCA3:

#40446080

and #40446130

RSCA6:

#40446080 and #40446090

RSCA10:

#40446080 and #40446110.

12) REPLACING PARTS

Ensure that at all times when parts are being replaced,

both gas and electrical supplies are disconnected. Various

parts are available from the factory for replacement by a

licensed person. Refer to the Replacement Parts Guide in

Section 14 for all replacement parts.

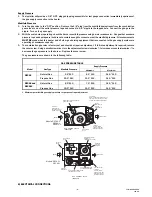

13) INSTALLATION DATA

Date of

Installation:

Number of

Heaters in System:

Heater Serial Number:

Heater Model:

RSCA

—

N = Natural Gas

L = Propane Gas

DO NOT DIRECT AN AIR HOSE A THE CERAMIC EMITTER SURFACE

AS IT MIGHT DAMAGE THE CERAMIC OR DISLODGE THE HIGH TEMPERATURE GASKET MATERIAL.