87

0716-M001-2-P1

8. PROBLEMS

TECNICAL SERVICE REQUIRED

do not attempt to do the job yourself

Some possible problems wich may arise while using the lift are listed below. The Manufacturer will not accept any

responsability for damage people, animals and objects caused by unautorized staff using the equipment. In the event of faults,

you are advised to contact the technical service department in good time to receive advice about how to carry out work and/or

adjustments in maximum safety conditions, thus avoiding the risk of damage to people, animals and abjects.

Turn the main switch to “0” and lock in case of emergency and/or maintenance to the lift.

FAULTS CAUSES

REMEDIES

No operation.

a)

b)

c)

d)

Main switch set to “0”.

Disconnected fuses.

Ropes loosening/breakage limit switch

tripped due to the breakage of a rope.

Ropes loosening/breakage limit switch

tripped due to the loosening of a rope.

a)

b)

c)

d)

Set switch to “1”.

Change blown fuses. If a fuse is blown

again, find the cause leading to the

inconvenience.

Change the rope. Contact dealer's technical

service.

Adjust rope with the special nuts positioned

onto post upper side. Contact dealer's

technical service.

Up movement is

possible, but down

movement is

impossible.

a)

b)

c)

d)

Ropes loosening safety limit switch tripped

due to an obstacle under the platform, or

due to the loosening of a rope.

Down solenoid valve EV1 faulty.

Solenoid valve EV3 faulty (catches).

Limit switch FC5 faulty (dangerous height).

a)

b)

c)

d)

Check ropes adjustment. Press UP

pushbutton until all ropes are tensioned.

Eliminate loosening causes. Carry out the

down movement.

To let platform move down, work manual

downstroke valve with the special key. To

remove and carry out the maintenance

operations on the down solenoid valve, refer

to Section MAINTENANCE.

Check solenoid valve correct operation and,

if necessary, clean it (see Cleaning sub-

section). Check air pipe and electrical cable

connection.

Check for FC5 cable correct connection

(refer to the Wiring Diagram).

Down movement is

possible, but up

movement is

impossible.

a) Motor heat probe disabled.

a) Wait for probe closing.

Lowering speed is very

low.

a)

b)

The flow controlvalve does not work properly

Clogged pipe.

a)

b)

Clean the valve (see § Valve cleaning)

Clean piston valve.

The motor turns

regularly but the lift

does not rise, or rises

slowly.

a)

b)

c)

d)

Descent solenoid valve jammed in open

position.

Pump intake filter clogged.

Piston gasket damaged or worn.

Pump worn or damaged .

a)

b)

c)

d)

Clean the solenoid valve (see § Valve

cleaning).

Clean the filter.

Replace the gasket.

Check pump for proper operation and

replace it if needed.

The lift cannot lift the

nominal capacity.

a)

b)

Faulty calibration valve.

Pump worn or damaged.

a)

b)

Request assistence from retailer's technical

service.

Check that the pump is working properly and

replace if necessary.

The release cylinders do

not work.

a)

b)

Release solenoid valve does not work

properly.

Release cylinder gasket worn or damaged.

a)

b)

Check that the spool of the solenoid valve is

working and clean the solenoid valve.

Replace the gaskets.

Summary of Contents for SQ 300

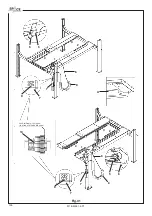

Page 80: ...80 0716 M001 2 P1 Fig 28 Fig 27 3...

Page 84: ...84 0716 M001 2 P1 Fig 29 3 1 2...

Page 104: ...104 0716 M001 2 P1 Fig 33 ARIA AIR 7 8 6 9 1 3 2...

Page 154: ...154 0716 M001 2 P1...