Installations

(refer to Page 4 for parts)

:

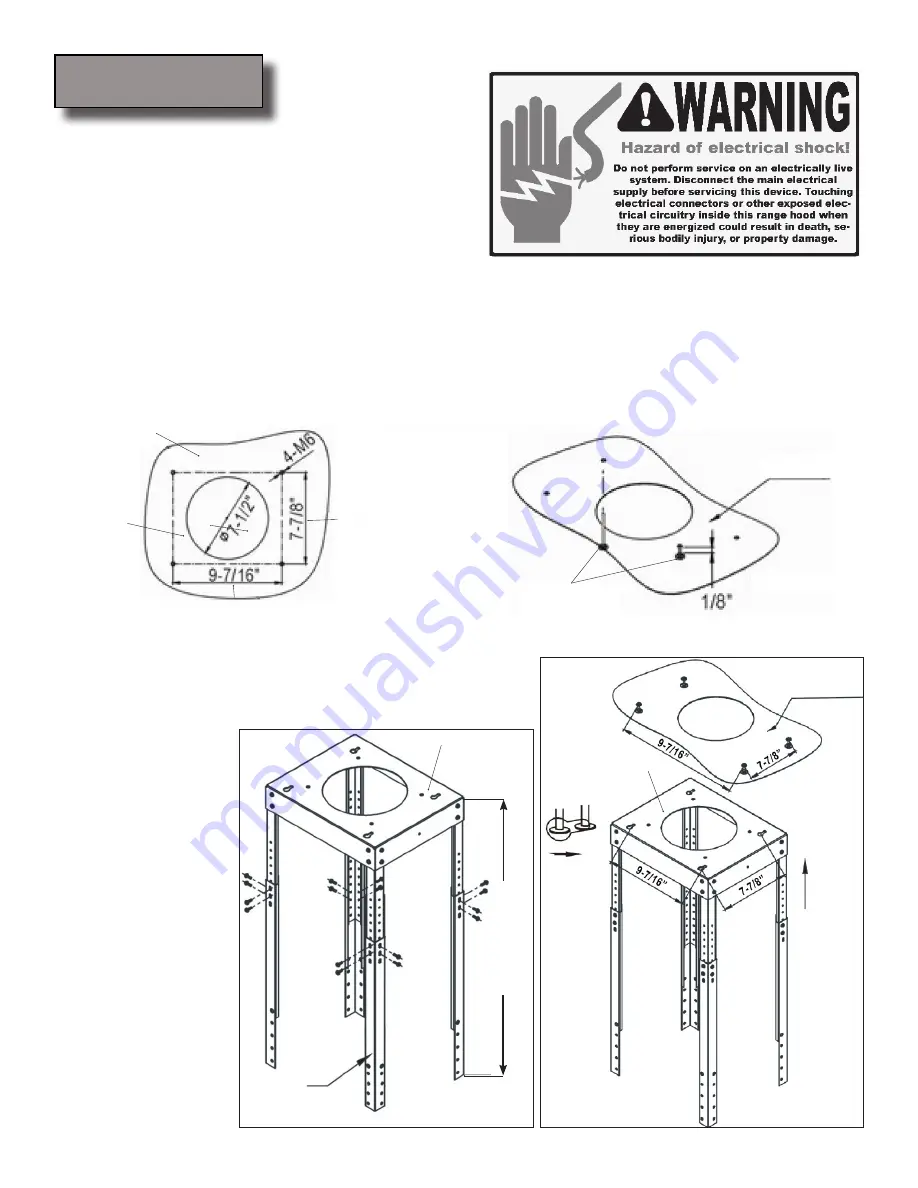

As illustrated in Figure 1A, drill four holes with diam

-

1.

eter not exceeding 5/8” and depth of 3” to 3-1/2” on the

false ceiling. Fasten two hexagonal wood screws at two

of these holes opposite from each other, reserve approx

-

imately 1/8” for the top support plate as shown in Figure

1B. Cut out a circle of 7-1/2” diameter for duct work. Use appropriate anchors for your ceiling composition:

Wood ceiling: Use the provided hexagonal wood screw.

•

Sheet rock ceiling: Attach top supporting plate to ceiling joists or stud blockings if possible. If ceiling

•

joists or stud blockings are not available, it is required to build a supporting structure behind the sheet

rock for best weight support.

Concrete ceiling: Use concrete sleeve anchor.

•

Place support frames inside the top support plate, adjust

2.

support frames to length required and lock the support

frames using sixteen (16) 4mm x 8mm Phillips Head Tap

-

ping Screw as shown in Figure 2.

Support

Frames

Length required

Figure 2

Align the holes in top

3.

support plate with two

screws on the ceiling.

Push upward (1) and

slide forward (2) so

the top supporting

plate locks into place,

see Figure 3. Fasten

two existing hex

-

agonal wood screws,

insert two more on

the last two holes

and fasten them..

CAUTION: MAKE

SURE the support

frame fixture is secure

before releasing!

Figure 3

Ceiling

(2) Slide

Forward

(1) Push

Upward

Front of the hood

Ceiling

Side of

the hood

Ceiling

Top

Support

Plate

Figure 1A

Figure 1B

Hexagonal

Wood Screws

Top Support

Plate

Top Support

Plate

Page 10

Installation