16

8. Maintenance and inspection

8.1 Maintenance

Check the water inlet and drainage often. The water and air inflow into the system

should be sufficient so that its performance and reliability does not get compromised.

You should clean the pool filter regularly to avoid damage to the unit caused by clogging

of the filter.

The area around the unit should be spacious and well ventilated. Clean the sides of the

heat pump regularly to maintain good heat exchange and to save energy.

Check if all processes in the unit are operational and pay special attention to the

operation pressure of the refrigerant system.

Check the power supply and cable connections regularly. Should the unit begin to

function abnormally or should you notice a smell from an electrical component, arrange

for timely repair or replacement.

Winterizing : make sure to purge all the water from the heat pump and other systems

in order to prevent frost damage.

You should also purge the water if the unit will not work for an extended period of time.

You should check all parts of the unit thoroughly and completely fill the system with

water before turning it on again afterwards.

8.2 Troubleshooting guide

Improper installation may result in an electrical discharge that could lead to death of

– or

serious injury to -pool users, installers or others due to electrical shock and may also cause

damage to property.

DO NOT

attempt to modify the internal configuration of the heat pump.

1. Keep your hands and hair clear of the fan blades to avoid injury.

2. If you are not familiar with your pool filtering system and heat pump:

a.

Do not

attempt to adjust or service without consulting your dealer or your professional

pool or air conditioning contractor.

b. Read the entire installation and user manual before attempting to use, service or adjust

the unit.

c.

Start the heat pump at least 24 hours after its installation in order to prevent

damage to the compressor.

Nota:

Switch off the power prior to maintenance or repairs.

19

Summary of Contents for SHP-100P

Page 6: ...6 ...

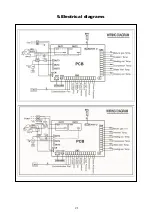

Page 21: ...16 9 Electrical diagrams 21 ...