PARTS LIST

ACCESSORIES

AVAILABLE

(

NOT SHOWN

)

3

1

XXXXXXX

XXXXXXX

VARIOUS MEDIA FOR TRAY 1

KEY

PART NUMBER

NO.

57N 5 7 P

DESCRIPTION

QTY.

1

W8

000

03N

W800003P

BURNER

ASSEMBLY

1

2

F

3

000

26

F

3

000

27

BURNER

ORIFICE

1

3

C1

000

3

6

C1

000

3

6

TS-12

BURNER

FLEX

CONNECTOR

1

4

C

2

000

01

C

2

000

02

MAIN GAS VALVE

W/STEPPER MOTOR

1

5

H2

000

13

H2

000

05

VENT-FREE

PILOT ASSEMBLY

1

6

C1

000

39

C1

000

39

PILOT

FLEX

TUBE

1

7

F

2

000

23

F

2

000

23

PILOT

MOUNT

BRACKET

1

8

H1

000

05

H1

000

05

3/8"NPS X

5

/

16

" COMP.

90 DEG. FITTING

1

9

C1

000

8

4

C1

000

8

4 3/8"NPS X 3/8" FLARE

90 DEG. FITTING

1

10

C1

000

09

C1

000

09

3/8" X 24"

FLEX. CONNECTOR

1

1

1

F

2000

66

F

2000

66

SUPPLIED

SHUTOFF VALVE

1

12

W8

000

08

W8

000

08

MEDIA TRAY (OPTIONAL, not shown)

1

13

W8

000

0

7

W8

000

0

7

INNER COVER

1

14

H2

00014

H2

00014

SPARK WIRE (V-F PILOT)

1

15

C1000

20

C1000

20

DUPLEX POWER OUTLET (not shown)

1

16

H2

000

01

H2

000

01

PROFLAME GTM TRANSMITTER

1

17

H

2000

10

H

2000

10

PROFLAME GTM RECEIVER 1

18

H1

001

4

0

H1

001

40

7V AC/DC POWER ADAPTER

1

19

H

100

142

H

100

142

SIT DFC CONTROL BOARD

1

20

H200012

H200012

VALVE WIRE HARNESS

1

21

H200011 H200011 GTM RECEIVER WIRE HARNESS 1

22 H200006 H200006 FLAME SENSOR WIRE (V-F PILOT) 1

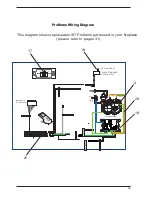

This list contains replaceable parts used in your firebox.

All replacement parts should be ordered from your installer or from Spark Modern Fires

at 1-8669-383-846

or on-line at www.sparkfires.com

23 F200022 F200022

VALVE MOUNT BRACKET 1