Page 34

Page 35

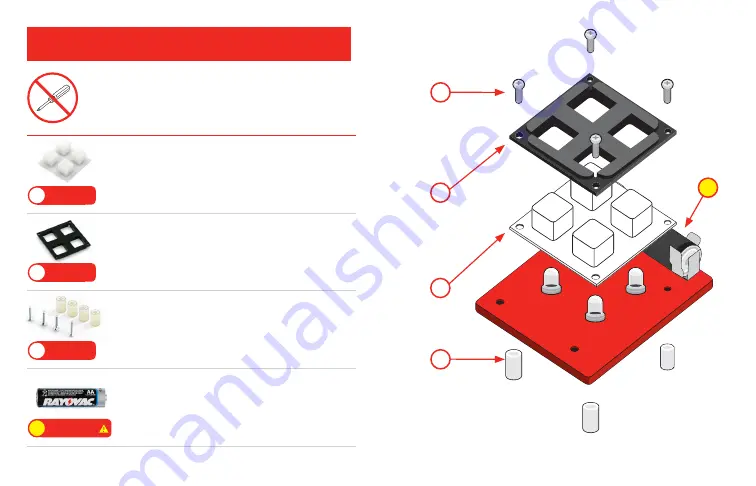

[ STEPS 35 T0 38 ]

FINAL ASSEMBLY

Screws x 4

37

AA Battery

(power source) Insert the battery, following “+”

and “-” indicators on the board. Turn on the board and verify

the LEDs are flashing.

Standoffs and screws

(mechanical) Insert the screws

through the bezel and button pad, then twist standoffs onto

the protruding screw. Hand tighten.

AA Battery

38

Bezel

(holds button pad) Attach to top. Lay bezel over button

pad, with notches for the screws pointing up.

Bezel

36

Button Pad

(game control) Attach to top. Lay rubber button

pad over LEDs.

Button Pad

35

No screwdriver necessary.

Please only hand-tighten the screws and standoffs.

38

37

37

35

36

TOP SIDE VIEW

Summary of Contents for Simon SMD

Page 22: ...Page 42 Page 43 Notes ...