15

Original instructions

EN

WARNING:

Always wear protective

gloves during maintenance operations. Do not

carry out maintenance when the engine is hot.

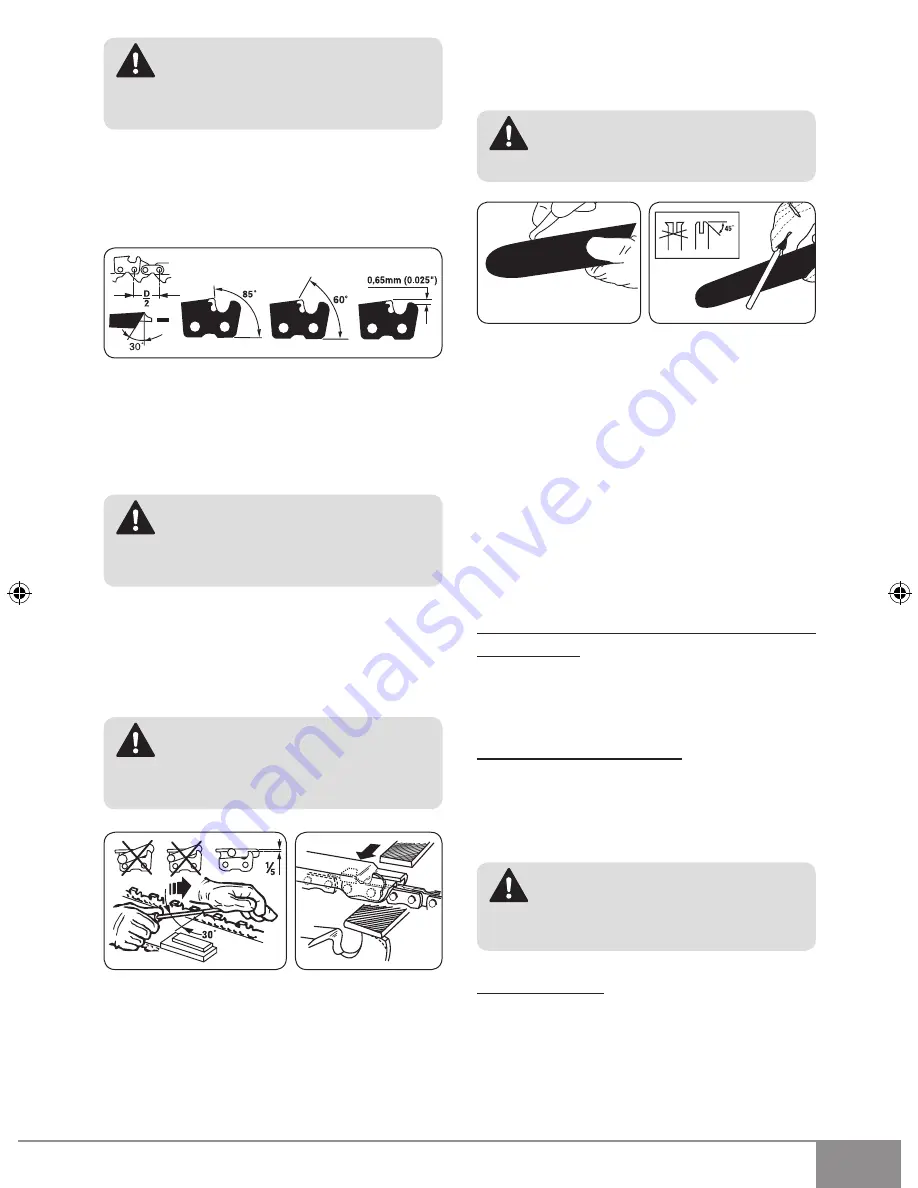

The pitch of the chain

(Fig. 24)

is 9.53 mm х 1.27 mm

(3/8” LoPro x .050”).

Sharpen the chain using protective gloves and a

round file of Ø4.8 mm (not included in the kit).

Fig. 24

Always sharpen the cutters only with outward strokes

(Fig. 25)

observing the values given in

Fig. 24

.

After sharpening, the cutting links must all have the

same width and length.

WARNING:

A sharp chain produces

well-defined chips. When your chain starts to

produce sawdust, it is time to sharpen.

After every 3–4 times the cutters have been sharp-

ened you need to check the height of the depth gaug-

es and, if necessary, lower them using the flat file and

template (not included in the kit), then round off the

front corner

(Fig. 26)

.

WARNING:

Proper adjustment of

the depth gauge is as important as proper

sharpening of the chain.

Fig. 25

Fig. 26

Guide bar

– The bar should be reversed every 8

working hours to ensure uniform wear.

Keep the bar groove and lubrication hole clean us-

ing the bar groove cleaner (not included in the kit)

(Fig. 27)

.

Check the bar rails frequently for wear and, if neces-

sary, remove the burs and square-up the rails using

the flat file

(Fig. 28)

.

WARNING:

Never mount a new chain

on a worn sprocket or self-aligning ring.

Fig. 27

Fig. 28

bar wear

– Turn guide bar frequently at regular in-

tervals (for example, after 8 hours of use), to ensure

even wear on top and bottom of bar.

oil passages

– Oil passages on the bar should be

cleaned to ensure proper lubrication of the bar and

chain during operation.

NotE.

The condition of the oil passages can be eas

-

ily checked. If the passages are clear, the chain will

automatically give off a spray of oil within seconds of

starting the saw. Your saw is equipped with an auto-

matic oiler system.

cHAIN mAINtENANcE

chain tension:

Check the chain tension frequently and adjust as of-

ten as necessary to keep the chain snug on the bar,

but loose enough to be pulled around by hand.

breaking in a new saw chain:

A new chain and bar will need chain readjustment af-

ter as few as 5 cuts. This is normal during the break-in

period, and the interval between future adjustments

will begin to lengthen quickly.

WARNING:

Never have more than 3

links removed from a loop of chain. This could

cause damage to the sprocket.

chain lubrication:

Always make sure the automatic oiler system is work-

ing properly. Keep the oil tank filled with SPARKY

chain, bar and sprocket oil.

Adequate lubrication of the bar and chain during cut

-

ting operations is essential to minimize friction with

pages-TV 3840.indd 15

12.4.2011 г. 13:18:24

Summary of Contents for TV 3840

Page 2: ...A 1 3 2 12 6 7 17 10 11 13 14 18 5 9 8 16 15 19 21 4 20 22 23 ...

Page 93: ... ...

Page 94: ... 1104R11 ...