Maintaining your

Attachment

Modifications

Modifications to the original design by the

end user may result in weakening the

designed structure and integrity of this

attachment and will void any warranty.

Before Every Use

Check that all fasteners (nuts, bolts,

pins, keepers) are in their right place

and are tight.

Lubricate all pivot joints using #2

lithium grease.

Inspect and replace any worn, torn or

missing safety decals.

Investigate the location of any oil leaks

and repair.

Every Week

Check the condition of the sweeper

wafers.

Lubricate all grease able pivot joints.

After Every Season

Inspect the attachment for any loose or

worn parts that may need to be replaced

prior to the next season.

Visually inspect the sweeper wafers.

Replace wafers as a set, if necessary.

Clean, sand & repaint any area that

looks worn or scratched to prevent

further rusting. Use an equipment paint

found at your local hardware store or

building center.

Lubricate all the pivot joints before

storage. If storing in a saltwater

environment, apply grease to the

exposed chrome cylinder rod(s). Store

your attachment in a shed or cover with

a water-proof tarp to protect it from the

weather. Store in an area not

frequented by children.

Hydraulic System

A small stream

of oil from a pinhole leak could

penetrate your skin if contacted.

To

avoid an accident that could result in

Death or Serious Injury, never use your

hand or other body parts in an attempt

to

locate a hydraulic leak.

Always release

the hydraulic system pressure from the

attachment circuit prior

to

removing the

attachment or any hydraulic system

service work.

Be kind to the environment. Repair any

hydraulic leaks immediately!

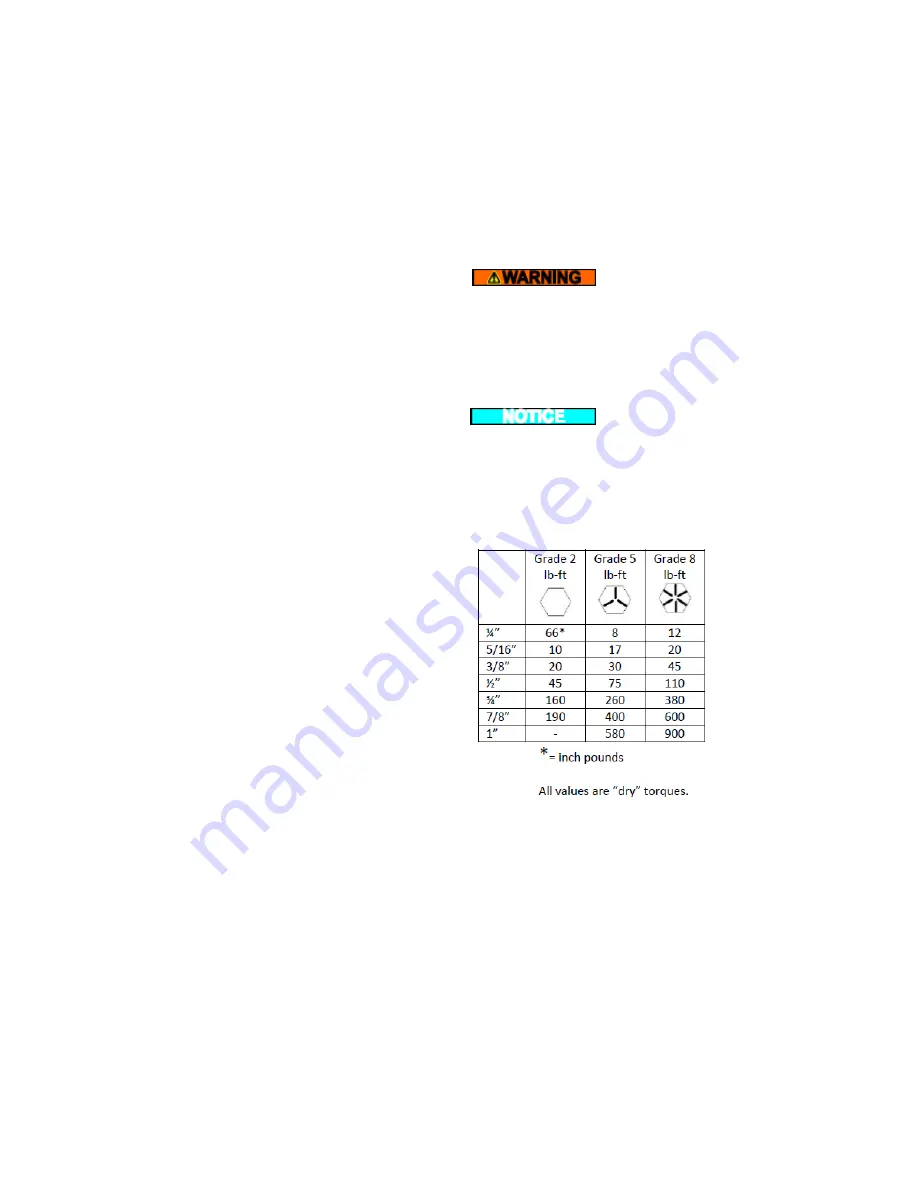

Hardware Torque

Spartan Equipment

PAGE 10

Angle Brooms June 2014

Summary of Contents for Angle Broom

Page 1: ...4...

Page 2: ...Spartan Equipment Joppa MD 21085 1 888 888 1085...

Page 13: ...Manual Angle Broom Parts Spartan Equipment PAGE 12 Angle Brooms June 2014...

Page 19: ...Spartan Equipment Angle Brooms June 2014 PAGE 18...

Page 20: ...Accidents Big or Small Avoid Them All Spartan Equipment PAGE 19 Angle Brooms June 2014...