7.

Engaging Broom the

First Time

If this is your

initial startup with this attachment

on

this machine, check the skid steer's

hydraulic oil level and add oil, if

necessary, before and after doing steps

1- 3

below.

After starting the skid steer, lift the

attachment 6" (152mm) off the ground

surface:

1.

With the skid steer engine RPMs just

above idle, slowly engage the

auxiliary hydraulic to spin the broom

bristles. Move the auxiliary control

pedal, lever or switch in the opposite

directions to reverse the broom's

direction. Repeat this three times.

2.

If your broom is equipped with the

hydraulically operated angle

feature, operate that function in

both directions three times also.

3.

Lower the broom attachment to the

ground and shut off the skid steer's

engine and exit the operator's

compartment.

5.

Check the skid steers hydraulic oil

level, and add oil if necessary.

6.

Inspect the broom's hydraulic

plumbing for any noticeable leaks.

Correct these leaks before

continuing.

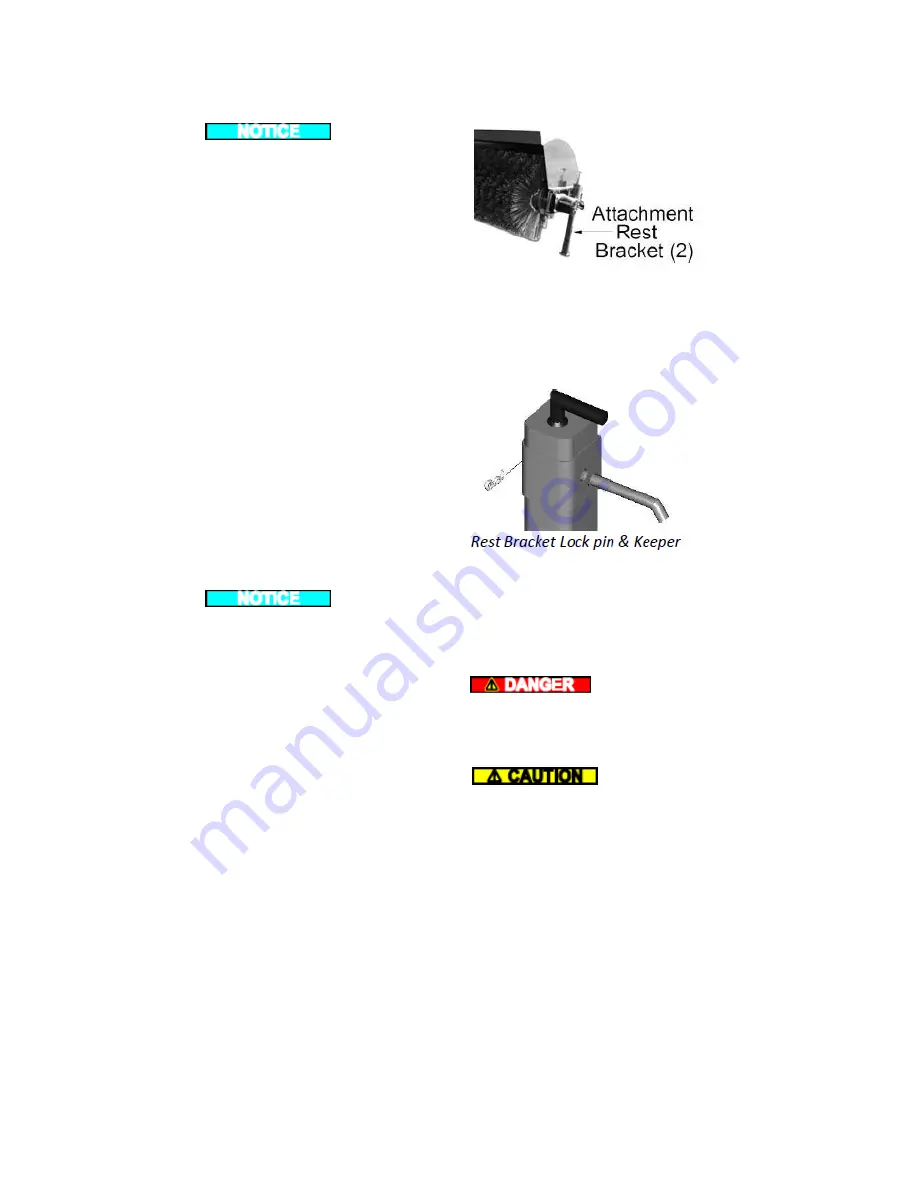

Stopping the Broom

The broom quits moving when the auxiliary

control is neutralized. When

you are done sweeping for a period of time,

always rest the broom attachment on the

brackets designed to support the weight of

the broom when not in use.

To raise the rest brackets, take the weight

off the rests by lifting slightly on the broom.

Pull the lock pin out of the rest bracket

tube and raise the tube to the position

where another hole lines up for the pin.

Insert the lock pin and keeper.

Getting Familiar with the

Attachment

Never operate

the broom when bystanders are within

100' (30

m)

of your work area. Flying

debris could result in Death or Serious

Injury.

Be cautious

when operating

on

un-level ground

surfaces. A machine roll over could

result in Minor or Serious Injury.

Always wear your seat belt when

operating this type of machinery.

Spartan Equipment

Angle Brooms June 2014

PAGE 7

Do not store the

broom while it is resting on the bristles as

the weight of the attachment over time will

warp or distort the shape of the bristles.

Summary of Contents for Angle Broom

Page 1: ...4...

Page 2: ...Spartan Equipment Joppa MD 21085 1 888 888 1085...

Page 13: ...Manual Angle Broom Parts Spartan Equipment PAGE 12 Angle Brooms June 2014...

Page 19: ...Spartan Equipment Angle Brooms June 2014 PAGE 18...

Page 20: ...Accidents Big or Small Avoid Them All Spartan Equipment PAGE 19 Angle Brooms June 2014...