8

2.3 SPECIFICATION

Conversion Factors

Inches to millimeters (mm): 1’’ = 25.4 mm

British Thermal Unit BTU/h to Watt: 1BTU/h =

0.293 Watt

Kilogramm to Pound: 1kg = 2.205 lb

Cubicmeter to cubicfeet:

1m3 = 35.314 ft

3

2.4 GENERAL INSTRUCTIONS

WARNING

THIS APPLIANCE HAS NOT BEEN TESTED WITH

ANY VENTED OR UNVENTED GAS LOG SET: TO

REDUCE RISK OF FIRE OR PREVENT INJURY, DO

NOT INSTALL A VENTED OR UNVENTED GAS LOG

SET INTO THE APPLIANCE.

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

This appliance and the components ARE DESIGNED TO BE

INSTALLED AND OPERATED AS A SYSTEM. ANY ALTER-

ATION TO OR SUBSTITUTION FOR ITEMS IN THIS SYSTEM,

UNLESS ALLOWED BY THESE INSTALLATION INSTRUC-

TIONS, WILL VOID THE LISTING AND MAY VOID THE PROD-

UCT WARRANTY. IT MAY ALSO CREATE A HAZARDOUS

INSTALLATION. READ THROUGH THESE INSTRUCTIONS

THROUGHLY BEFORE STARTING YOUR INSTALLATION AND

FOLLOW THEM CAREFULLY THROUGHOUT YOUR PROJECT.

• Before beginning your installation, consult with

your local building code agency or fire officials and

insurance representative to ensure compliance.

• Non-toxic smoke will be emitted during the paint

curing process, to help dissipate the smoke open a

window near the appliance.

• Remove any dust or debris off the top of the appli-

ance before firing the appliance as the paint will

become soft as the appliance heats up and will

harden as the appliance cures. To cure the paint on

your appliance burn your appliance moderately hot

during the first few fires.

• To keep the gasket from sticking to the appliance

as the paint is curing, periodically open the door

every 5-10 minutes.

• For the first two weeks use generous amounts

of fuel and burn the appliance for an hour as the

appliance goes through a process of eliminating

moisture in the steel and refractory bricks. The ini-

tial heat output will be reduced while the moisture

is being drawn from the appliance and it will be

necessary to build several hot fires to remove this

moisture. DURING THIS PROCESS DO NOT OVER-

FIRE THE APPLIANCE.

2.5 GENERAL INFORMATION

The chimney vent system used on your wood burning

appliance should be designed with the least amount

of restriction possible to enable the exhaust products

to easily flow through it. Chimney vent systems that

are too short or too long (refer to point 4.3 ”chimney

installation”) can also have an adverse affect on the

flow of exhaust through it. The wood burning appli-

ance and chimney vent system also require a suffi-

cient supply of combustion air not only to support the

combustion in the combustion chamber but to replace

the exhaust leaving it so it can flow freely up through

the vent system and out into the atmosphere. It is the

correct balance of combustion air and the chimney

vent system that will ensure the appliance provides

you with its optimum performance.

Be sure to provide sufficient combustion air. There are

many other appliances in your home competing for

air such as a kitchen range hood, forced air heating

devices or a bathroom exhaust fan.

Expansion / contraction noises during heating up and

cooling down cycles are normal and to be expected.

After extended periods of non-operation such as

following a vacation or a warm weather season, the

appliance may emit a slight odour for a few hours. This

is caused by dust particles on the firebox burning off.

Open a window to sufficiently ventilate the room.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

If you experience smoking problems, you may need

to open a door, a window or otherwise provide some

method of supplying combustion air to the appliance.

CAUTION:

These modules are not certified for gas log sets.

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institute® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

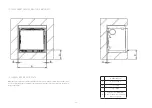

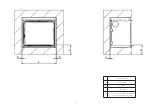

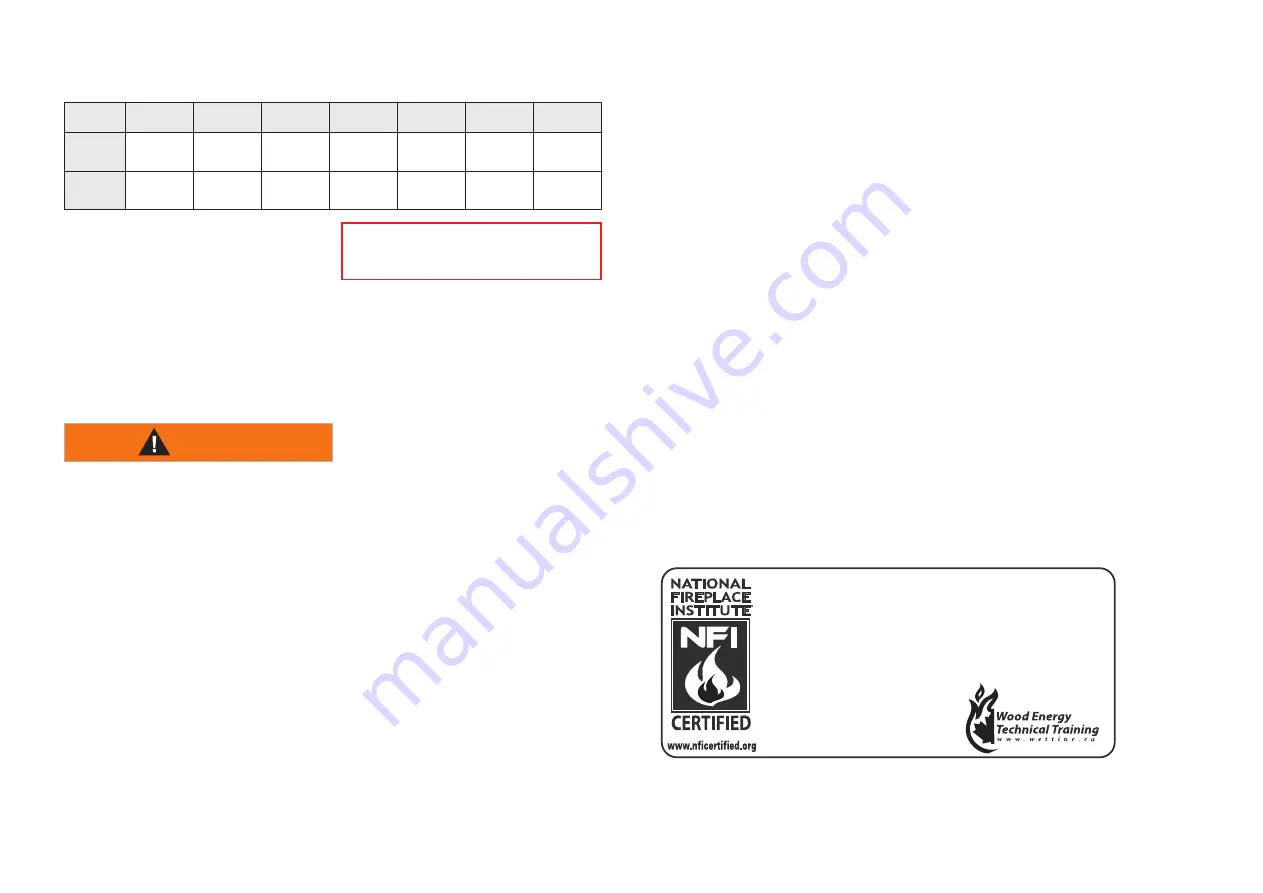

Fire chamber

volume

Minimum Power

Maximum power

Efficiency*

Chimney type

Unit weight

ideal fuel size

ZC

FIREPLACE-600

0,95 ft

3

10 613 BTU/h

47 417 BTU/h

70.29 %

USA: 6”x2” + USA

6”+7” HT2100

CANADA: 6”x1”

265lbs / 120kg

17"

ZC

FIREPLACE-700

1,58 ft

3

13 129 BTU/h

49,000 BTU/h

66.77 %

USA: 6”x2” + USA

6”+7” HT2100

CANADA: 7”x1” only

298lbs / 135kg

21"

Summary of Contents for 600-ZC

Page 19: ...19...

Page 28: ...28 10 6 FOR YOUR INFORMATION...