GB

GB

17

6. Place the glass panes supplied in the bushes in the top side. (Fig. 5)

7. Plug the mains power unit into a socket.

Important notes for assembly and setup

• No gradients are permitted on the pipework of the drain hose.

• The drain hose must not exhibit a U shape.

• The ethanol canister must be set up at least 0.5 metres below the

burner, and not more than 4 metres below it.

3.4.2 STARTING THE EBIOS-FIRE

1. Actuate the switch on top of the appliance. This establishes operational

readiness. You can shut down the appliance at any time with this switch.

(Fig. 6)

2. To do this, press the top button on the remote control (Fig. 7). To shut it

down, press this button once again.

3. The red illuminated ring on the switch on the top of the burner lights

up. The burner then beeps twice briefly, then starts the filling process.

Initially, the ethanol collects in the middle of the burner channel. Once it

reaches the right level, it can be ignited. Wait until the pumping action

has stopped and for the end of the ignition interval.

Never bend with your head directly over the burner channel, especially

not during the ignition phase.

Keep a safe distance of 1 metre away until the appliance has ignited

the fuel.

Initially, the flames are scarcely visible, especially while the fuel is

still cold. As the burner channel heats up, the flames get higher and

brighter.

4. If the level when hot is significantly higher at one end of the burner

channel than it is at the other end, it must be adjusted using an Allen

key on the adjusting screws on the frame.

Never perform adjustments while the appliance is lit. Never bend

directly over the burner channel.

Fig. 6

Fig. 7

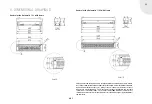

Fig. 1

Fig. 2

2

3

1

1

Low-voltage connector

2

Fuel connection

3

Overflow

Fig. 3

Fig. 4

Fig. 5